- Home

- Users & Science

- Find a beamline

- Collaborating research group beamlines

- BM32 - IF - InterFace Beamline, French CRG

- Beamline description

- Laue Microdiffraction (Laue)

Laue Microdiffraction (Laue)

Laue Microdiffraction (µLaue)

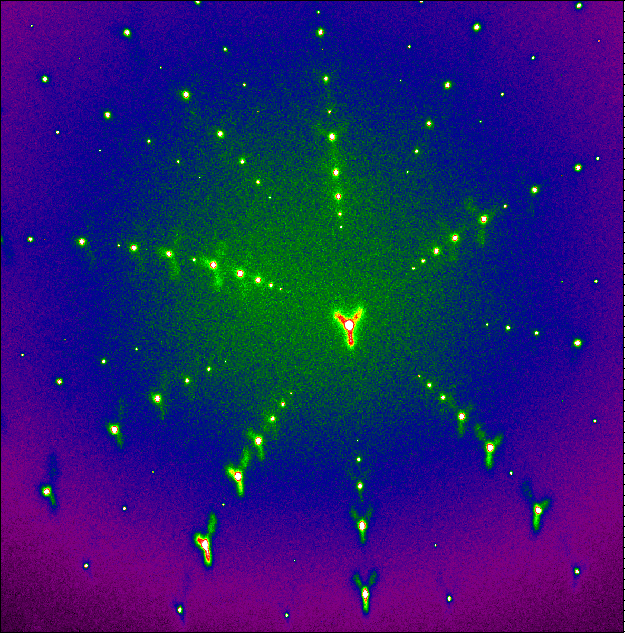

The large demand for structural characterization of objects with ever decreasing sizes has driven the development of new methods to determine not only the average internal structure but also the local structure at submicron scale. Probing the local strain, shape (size, orientation) and composition of micro and nano materials is the main objective of our Laue micro-diffraction setup. This dedicated setup is unique in Europe. Such instrument takes full profit from the white beam source of bending magnets.

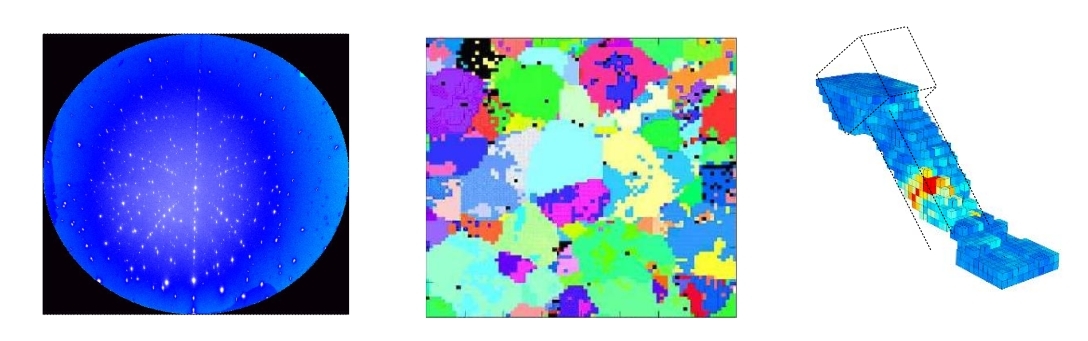

Presentation Poster of X-Ray Laue Microscopy (August 2023)

Please refer to cababilities described in our exhaustive last 5 years activity report. The page below gives main aspects of the technique. Don't hesitate to contact BM32 staff.

Last 5 years Laue microdiffraction and LaueTools publications

The microdiffraction setup is operational since 2006.

The enhanced station for Laue microdiffraction LaueMAX is coming soon!

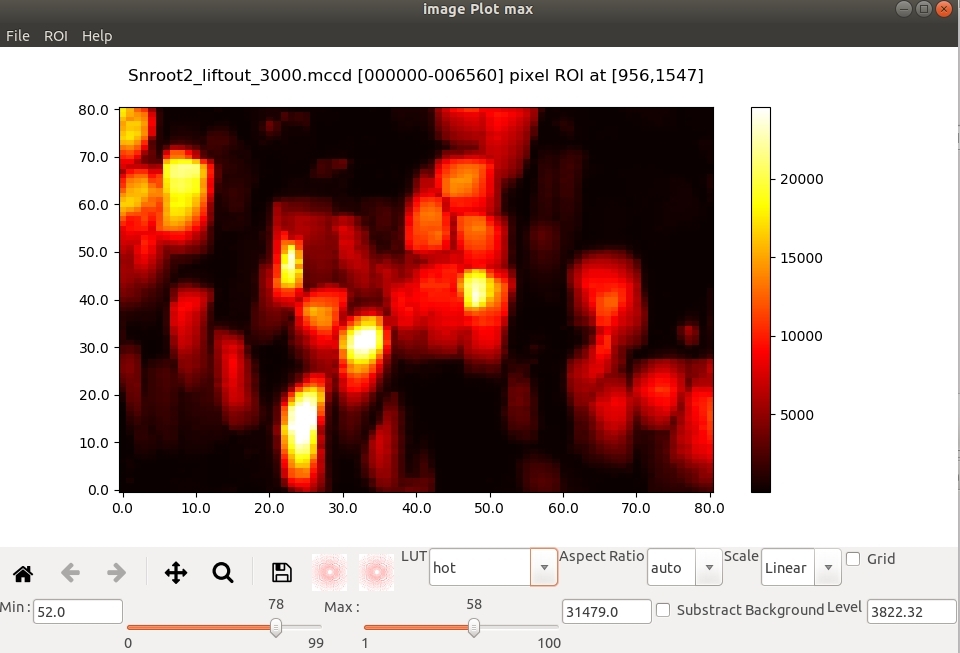

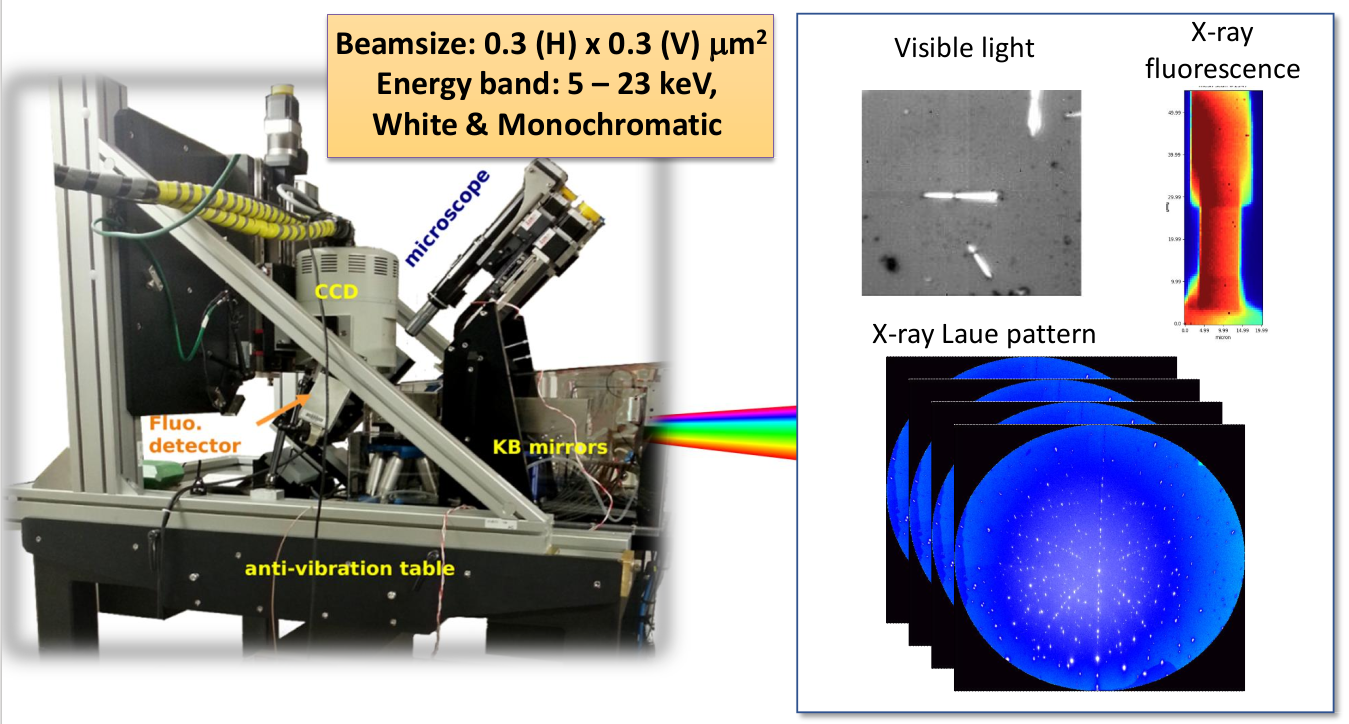

Two fixed-curvature elliptical KB mirrors are used to achieve a sub-micronic (hxv) =0.3x0.3 µm2 white beam with a X-ray energy range of 5 to 23 keV (adjustable) up to 2018. Now (sept. 2020) thanks to EBS and new Rh-coated KBs: (hxv) =0.2x0.2 µm2 and energy band 5-22 keV. A typical Laue pattern on a thick grain (>5µm) requires less than 0.5s counting time. Larger counting times are needed for low Z materials, smaller grains (< 0.5 µm), and grains with large orientation gradients (> 10 mrad/µm).

Selected regions of interest on the sample surface can be finely aligned on the x-ray beam by means of an optical microscope featuring a 50X objective and a 12X zoom, low depth of focus (< 1 µm) and high lateral resolution (0.3µm). In addition, x-ray fluorescence mapping can be used for locating micro-markers on the sample when the microscope is retracted.

|

|

Laue Microscopy is based on the collection of Laue pattern of scattered beams coming from white and microsized beam sample illumination. Beam properties correspond to the 2015-2018 period. |

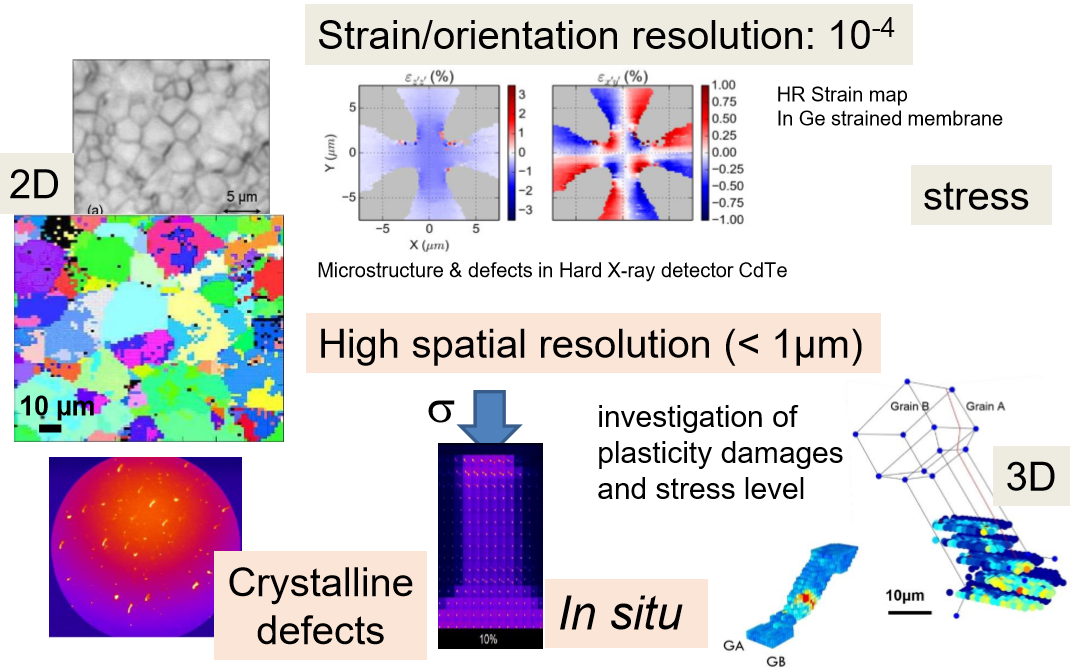

The spot positions in the Laue pattern can be monitored as a function of time to detect in situ phase transitions, crystal deformation or reorientation. The mapping of the spots positions as a function of beam position on sample helps to localize regions where stresses or defects concentrate, e.g. after sample elaboration or after applying a load.

At a higher level of analysis, each single Laue pattern once indexed fully determines the grain orientation (3 Euler angles) and the deviatoric shape of the unit cell (i.e. b/a, c/a, ). Large orientation maps built from a raster sample scan then provide e.g. the local texture and the relative strain levels of between grains of different orientations. Such maps also allow selecting particular grains for fine intra-grain mapping of orientation and strain gradients. Complementary methods for spot energy measurements (monochromator, energy dispersive detector, transmission Diamond monochromator) may then be used for local full strain tensor or line profile analysis. Moreover, 3D scan are now available thanks to optimized DAXM technique and new numerical algorithms developed on the beamline last years.

Laue Microscopy provides local structural parameters (orientation, strain and stress tensor) with high resolution on mono- and poly-crystals by 2D or 3D mapping. In situ experiments can be carried in various conditions.

Applications of this instrument are mostly in Materials Science: energy-related materials (Solid-oxide fuel cells, nuclear fuels, photovoltaic cells), complex integrated circuits from the micro-electronics industry (2D and 3D interconnects), structural materials (superalloys for turbine blades, and other metallurgical compounds), biology-related materials (wood, tooth, nacre) for orientation and texture aspects. More fundamental studies include in situ mechanical testing on model macro, micro or nano objects (FIB-machined metallic micro-pillars, nanowires, whiskers, bi-crystals, tri-crystals), in view of improving the description of the mechanical properties of polycrystals or micro and nano objects in elastic or plastic regime (peak shape analysis).

Polychromatic beamsize on sample (Full-Width-at-Half-Maximum):

horizontally : 0.3 micrometer

vertically : 0.3 micrometer

When using the sample translation stages, sample surface is tilted by 40 degrees with respect to the beam and the horizontal plane. This inclination increase by approximately 50% the actual footprint of the beam in the vertical direction only.

Spectral energy ranges currently from 5 to 22 keV

High energy limit can be lowered by changing optics mirrors angles down to typically 12-15 keV. This setup is suitable for disentangling Laue Patterns coming from many grains with large amount of peaks (large unit cell dimensions or/and atoms with high Z values)

Installation and Alignment duration

Optics alignement to deliver a focused beam takes from 1 to 3 hours. Generally, the setup is already ready before starting an user experiment. However, to collect the first valuable data and define the proper acquisition strategy may require 8 hours after the beginning of the experiment (exposure time, step resolution, mounting the sample, locating region of interest...), in particular for in situ or operando experiments.

Data Analysis ;-)

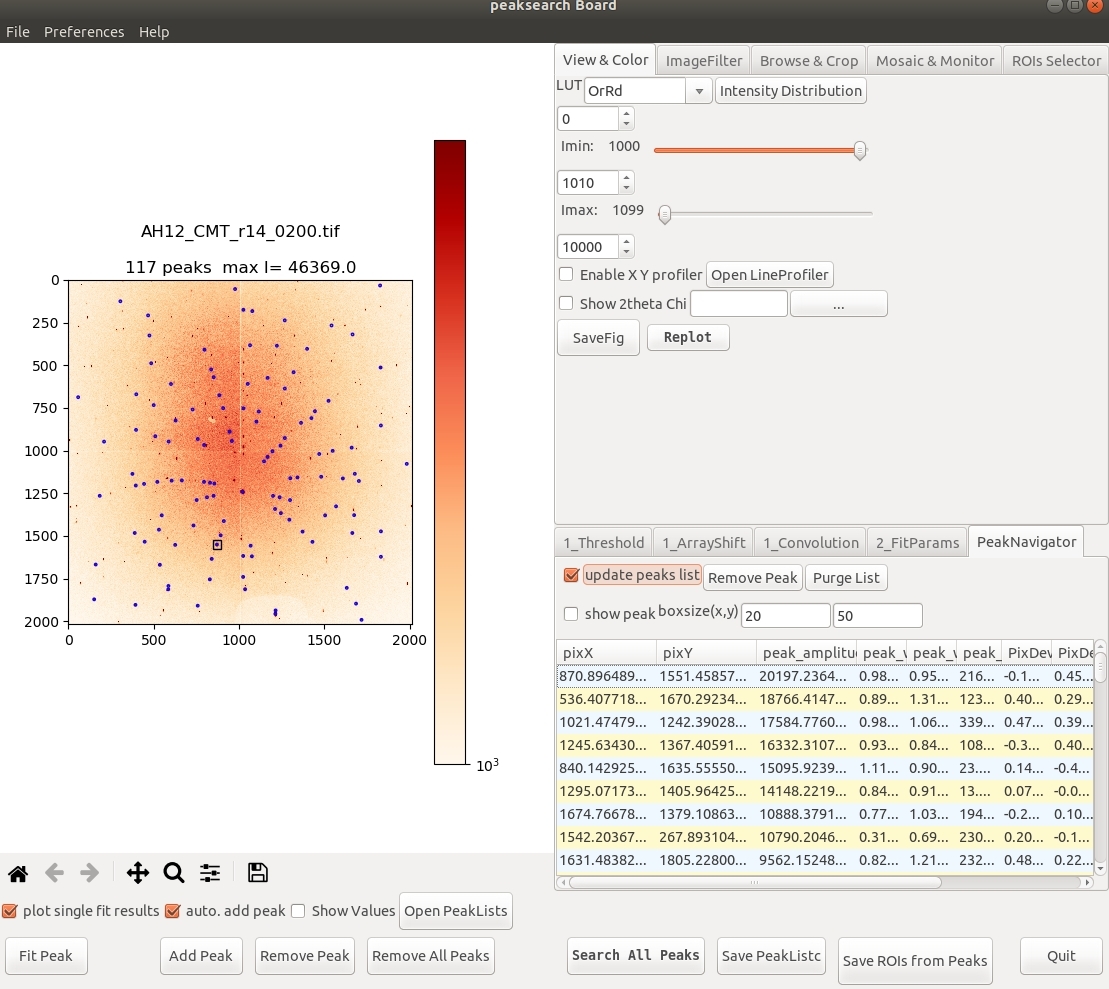

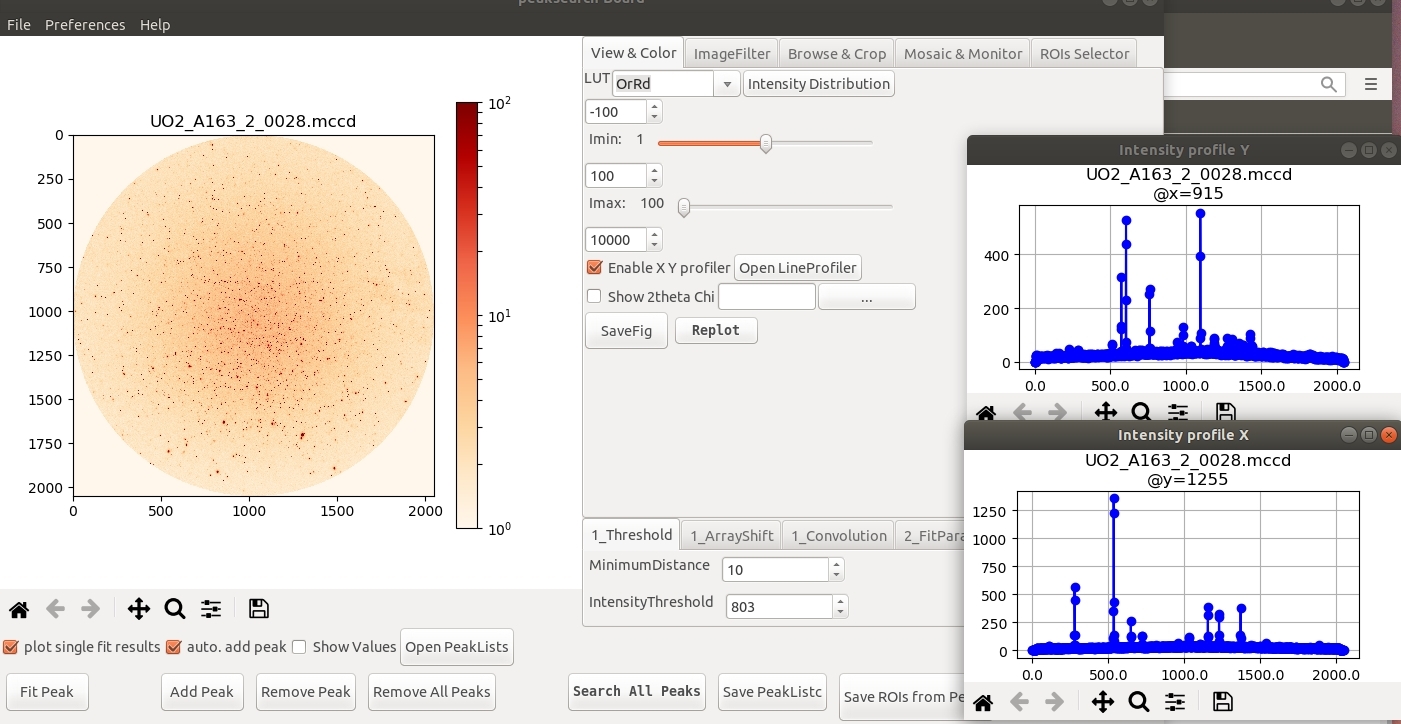

Laue Microdiffraction Data can be handled and reduced by the home-developed and open source Software: LaueTools

Recently a new route of indexing based on Neural Network (deep learning) is available, also as an open source software: LaueNN

Software packages development:

LaueTools and LaueNN software for Laue microdiffraction data analysis are open source.

They can be used on the beamline at ESRF or downloaded. See http://github.com/BM32ESRF

Data Analysis with LaueTools

Laue Microdiffraction Data can be handled and reduced by the home developed and open source Software: LaueTools

LaueTools software package development:

LaueTtools Open source codes are on github since end of 2022:

https://github.com/BM32ESRF/lauetools

Online Documentation (under permanent construction)

Some Notes on LaueTools conventions

Browse the codes: https://github.com/BM32ESRF/lauetools/tree/master/LaueTools

You can install lauetools running with python 3 on windows 7, windows 10 & linux by the command:

pip install lauetools

More details for one good way to install it : installation guide

Presentations:

Laue Microscopy presented at workshop "new opportunities in Diffraction Microscopy" (January 2024)

Poster of Laue Microdiffraction on BM32 (August 2023)

A webinar (in french) organized by the GDR COnCOrD (on youtube) (June 2022)

Tutorial document for HERCULES school (March 2020): Laue Introduction

LaueTools & LaueNN tutorial video : user meeting (February 2022) on youtube

Some movies to discover quietly the world of Laue diffraction (Schools and Training Sessions)

ANF Laue Microdiffraction: de la mesure à l'analyse (sept.2017): Data analysis (in french)

Scisoft Meeting at ESRF: "LaueTools: a software package for Laue MicroDiffraction Data Analysis" (29th July 2010)

Laue Microdiffraction: Ecole GDR MECANO Autrans (March 2010) : tutorial

BeamLine Review Panel 2010 one page general presentation of the microdiffraction setup available at this date.

Laue Microdiffraction: Workshop GDR MECANO (september 2009): Automatic analysis: dream or reality ?

Laue Microdiffraction: Workshop GDR MECANO (september 2009): LaueTools

LaueTools Screenshots & Examples:

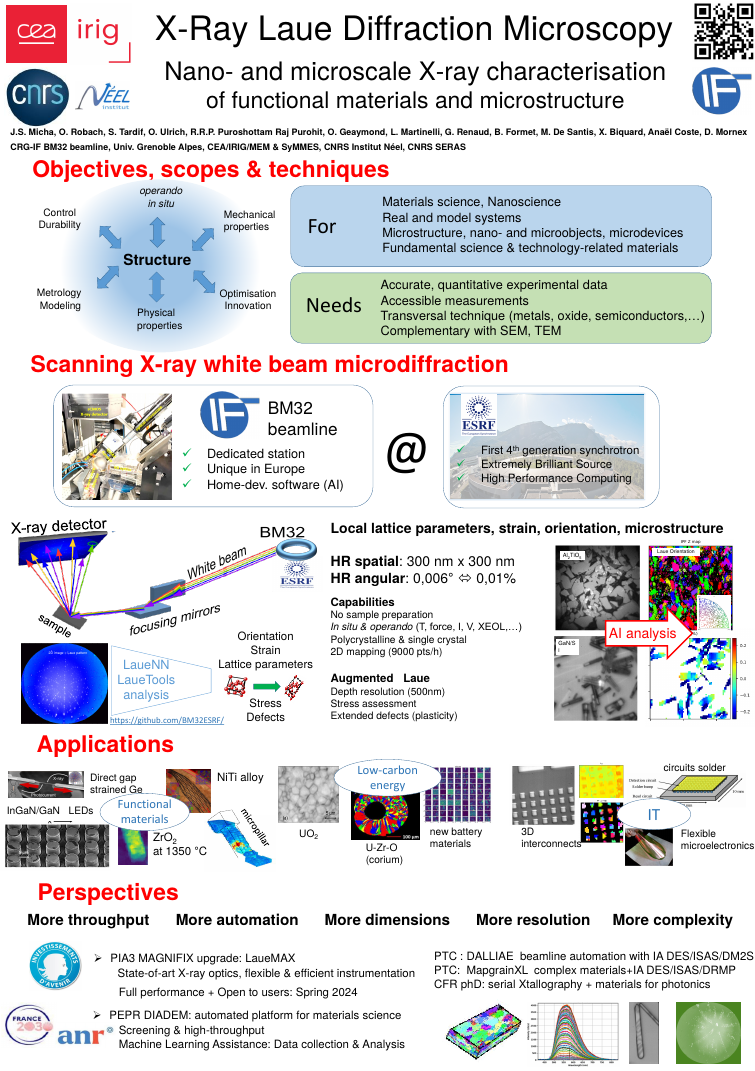

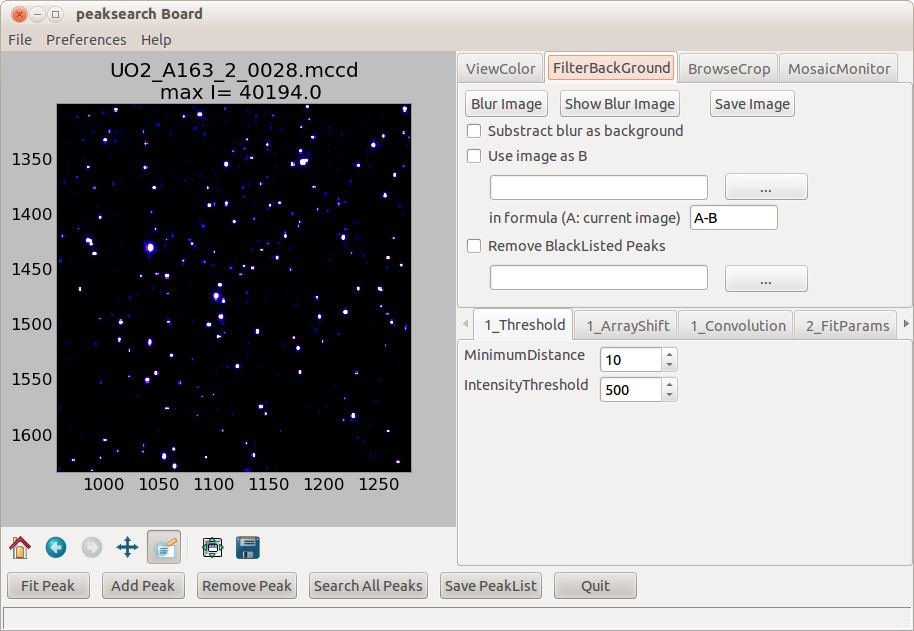

pre -analysis based on images analysis

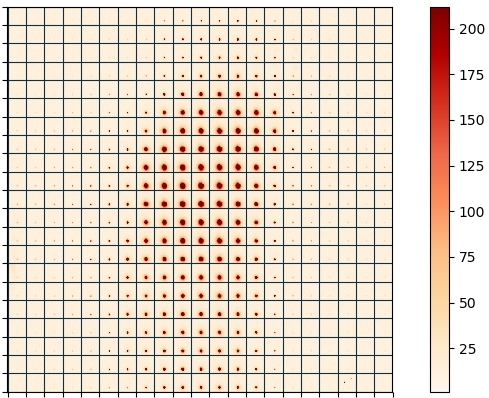

from a set of images (collected during a sample scan or with time or experimental parameter) to visualise and select sample ROIs for further measurements or finer analysis...

Mosaic plot: 2D map of a given Laue spot (grid corresponds to sample position)

2D map of numerical scalar quantity from a given ROI of the 2D detector

peak search

single image analysis

batch analysis

indexing

single image analysis

batch analysis

Multiple grains Simulation

twins, deformation rotation, texture

peaks elongation (slip systems)