- Home

- Users & Science

- Find a beamline

- Collaborating research group beamlines

- BM32 - IF - InterFace Beamline, French CRG

- Beamline description

- In Situ Nanostructure and Surface (INS2)

In Situ Nanostructure and Surface (INS2)

General presentation of the INS2 station

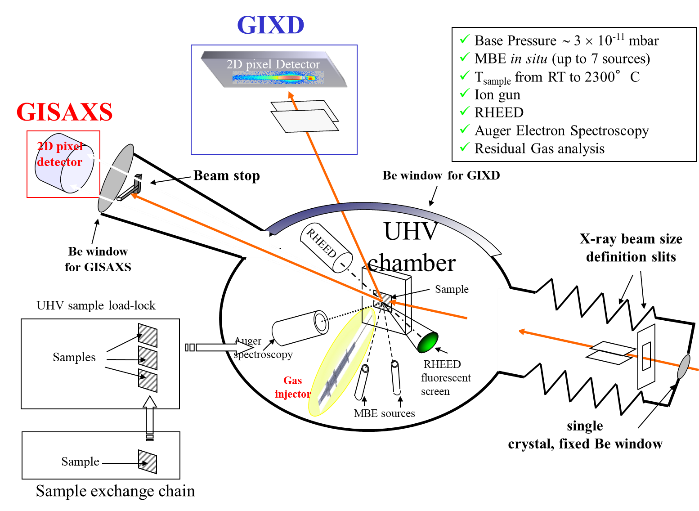

The new INS2 (since 2016) is dedicated to in situ studies of the growth and structure of nanometric films, particles, nanowires or new 2D material, possibly operando and in real time, using diffusion/diffraction of hard X-rays. The growth is achieved using a combination of techniques including molecular beam epitaxy (MBE) and chemical vapor deposition (CVD). X-ray measurements allow, among other things, structural studies on the atomic scale by grazing incidence scattering at large angles (GIXS/GIXD/SXRD/XRR) and morphological studies on the scale of a few nanometers or tens of nanometers, by scattering at small angles in grazing incidence (GISAXS). The GIXS and GISAXS techniques can be used simultaneously in real time.

|

Photograph of the X-ray station of the INS2 setup. |

|

|

|

Schematic drawing of the principles of the INS2 setup |

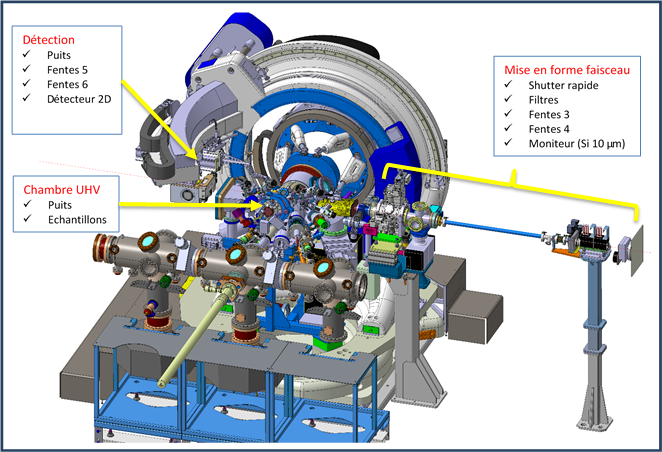

The CAD representation of the whole setup |

Main characteristics of the motions

| Goniometer | Sample holder (hexapod) | |||||

| Circle | incidence (deg) |

out-of-plane |

in-plane scattering (deg) |

sample azimuth (deg) |

cradle (deg) |

translation (mm) |

|

Mechanical resolution |

0.0007 | 0.006 | 0.001 | 0.0005 | 0.001 | 0.001 |

| Range | -1/+20 | -1/+45 | -13/+126 | ±200 | ±5 | ±5 |

| Concentricity (µm) | ~30 | ~30 | ~20 | |||

| Encoder resolution | 0.0004 | 0.0003 | 0.0004 | 0.00004 | ||

| Repeatability | 0.001 | 0.001 | 0.001 | 0.001 | 0.002 | 0.005 |

Compared to the previous instrument, INS2 can move the sample or the detectors 10 to 100 times faster, making it possible to study the nucleation/growth processes of quantum dots or 2D films or nanowires on a more relevant time scale. It also allows more structural and / or morphological information to be collected simultaneously by recording maps of the reciprocal space using fast 2D detectors. Finally, all these studies can be carried out under much better and more complex conditions.

The UHV chamber is designed as a hybrid system. First, it allows “classic” ultra-vacuum studies including heating up to high temperatures (1500°C standard; up to 2350°C with a special, non-transferable sample mount), ion bombardments, Auger electron spectroscopy and Reflection High Energy Electron Diffraction measurements, as well as measure of partial pressures of residual gases or of gases injected into the chamber. Second, it also accepts samples that are transferred from other processing chambers equipped with 1-inch Moly-block, thanks to two specific UHV transfer suitcases. Third it can be used to grow different nanomaterials by MBE or by CVD or by combining the two growth methods. A large number of evaporation sources are available, either of the "Knudsen" type or of the electron bombardment type. More than 8 can be simultaneously mounted on the chamber. A very specific injector associated with a versatile and secure gas distribution system is available for the CVD. Nitrogen and hydrogen plasma sources as well as a large source of silicon are also available. This chamber is fitted with a large number of flanges of different diameters and easily accessible, making it possible to envisage very varied configurations, rarely available on similar instruments.

Summary of specific properties

Specific properties when compared to other surface diffraction stations at ESRF:

- The shared beam time with the other station makes it possible to investigate systems that require significant preparation before performing an X-ray experiment ( the UHV and the MBE chamber can be available before an experiment).

- RHEED, XRR, GIWAXS, GISAXS experiments on the same sample.

- Co-deposition: simoultaneous use of up to 10 physical evaporation sources and UHV-CVD (3 gas lines)

- Better signal to noise performances for samples with large mosaic spreads (~0.1°) because of the large horizontal beam divergence.

- Fast sample introduction system.

- High temperature furnace (up to 1500°C).

- Special non tranferable mounting allowing for sample flashes up to 2400°C

- The beam energy can be changed easily and continuously.

- The transfer system makes it possible to produce samples in other chambers or to characterise the same sample with complementary techniques in the different chambers.

READ MORE in ins2_description.pdf