- Home

- News

- General News

- Piezoelectric ceramics...

Piezoelectric ceramics go textured

07-04-2023

A team of scientists created a piezoelectric material with outstanding electromechanical properties by using a novel texturing process to align ceramic grains along specific crystallographic orientations. The results are published in Science this week.

Piezoelectric materials are characterised by coupling between mechanical and electrical fields, and are at the core of transducers, actuators, and sensors in many electromechanical technologies. Commercial piezoelectrics are found as both single crystals and polycrystalline ceramics: single crystals generally have stronger electromechanical response, while ceramics can be more easily manufactured into a range of compositions, shapes, and sizes, and are therefore widely applied in the industry.

Thanks to their high piezoelectric properties, combined with ease of manufacture and low cost, lead zirconate titanate [Pb(Zr,Ti)O3, PZT] ceramics have found their way into countless piezoelectric devices used in precision manufacturing, medical imaging/therapy, and energy harvesting. Meanwhile, the increasing demands of modern technologies in terms of electromechanical properties, temperature range and stability has spurred much research effort to improve PZT ceramics. Among the approaches explored in recent years, fabrication of textured ceramics is considered an effective means to achieve high piezoelectricity while maintaining high thermal and depolarisation stability (expressed respectively by Curie temperature TC and coercive field EC).

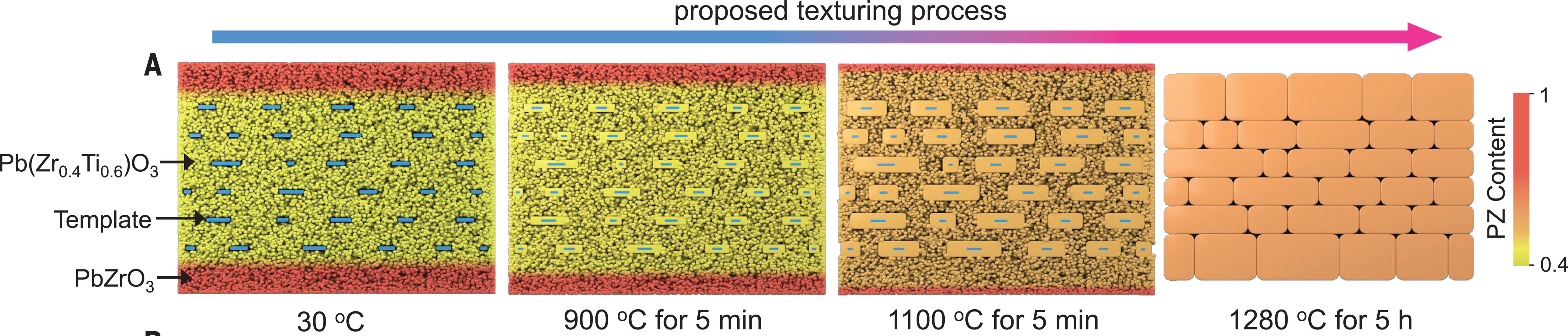

Engineering grain orientation in PZT ceramics, however, has proved especially difficult due to chemical reaction between PZT and texture-inducing templates, which are micron-sized crystals with a large aspect ratio. Now, scientists led by the Xi’an Jiaotong University and Harbin Institute of Technology (both in China) and the University of Wollongong (Australia) introduced a method to make textured PZT ceramics with outstanding properties, including TC of 360°C and piezoelectric coefficient d33 of 760 pC/N. Their approach was two-fold. First, they found an optimised template based on oriented Ba(Ti,Zr)O3 microcrystals. Secondly, they designed a “seed-passivated” texturing process, where two tape-cast slurries with different chemical compositions are interleaved, to suppress reaction between PZT and template. As a result, <001>-aligned grains grew at the expense of randomly oriented grains during sintering, finally producing textured PZT ceramics with controlled, uniform composition.

|

|

Schematic illustration of the proposed texturing process. The color of the PZT matrix indicates its composition. Credits: Li, J., et al., Science. |

In the article, the scientists present the microstructure, electromechanical properties, polarisation and strain of the textured PZT ceramics. They used high-energy X-ray diffraction (XRD) at beamline ID15A of the ESRF to determine first the {200} pole figure, revealing a volume fraction of around 94% aligned grains and thus a high degree of texturing. Then, they studied the ceramics during application of electric field by time-resolved, in situ XRD, providing simultaneous texture and strain information at multiple orientations within the sample. "On one hand you need high flux at 80 keV, or higher, to get diffraction from bulk PZT while electric field ramps at several kV/s; on the other, this wouldn't be possible without a fast area detector and micron-precise sample positioning. ID15A manages all of that," says Stefano Checchia, scientist at ID15A.

In situ XRD results demonstrated that the strain mechanism in textured PZT is essentially a polarization rotation process between two crystallographic directions. “Importantly, we found that the high piezoelectricity of <001>-textured PZT ceramics is due to intrinsic lattice contribution (electric-field-induced lattice deformation) instead of domain wall motion, which is typically considered the major contributor to the piezoelectricity in traditional 'soft' PZT ceramics”, explains Fei Li, professor at Xi’an Jiaotong University and one of the corresponding authors of the paper.

The results are expected to have a strong impact on future applications of piezoelectrics: “Given the ever-increasing demands on performance, particularly from the medical diagnostics and precision manufacturing industries, these developments will contribute significantly to the advancement of technology and innovation in these fields, paving the way for more efficient and accurate applications that can benefit society”, explains John Daniels, scientist at the University of New South Wales and author of the paper.

Reference:

Li, J. et al, Science 380(6640), 87-93, DOI:10.1126/science.adf6161

Top image: Schematic illustration of a step in the proposed texturing process. The color of the PZT matrix indicates its composition. Credits: Li, J., et al. Science.