Megahertz X-ray diffraction imaging of a propagating fracture in a brittle material

The combination of an ultra-high-speed camera with intense, stroboscopic synchrotron radiation at ID19 has enabled the in-situ imaging of cracks in silicon wafers as they propagate at high speed. This imaging technique provides a comprehensive view of controlled fracture propagation in a crystalline material.

A broad range of applications rely on the ability to control the propagation of cracks in brittle materials, from the mitigation of damage, e.g., from impacts on glass screens or vehicle windscreens, to industrial processes harnessing fracture to achieve clean cuts over large distances.

The world leading company on semiconductor materials, SOITEC, uses a crack propagation method called the SmartCut process to transfer single-crystal semiconductor thin films on receiver substrates by fracturing an implanted layer in the material in a controlled manner. Meeting the specifications of next-generation substrates requires a finer understanding of crack propagation; however, studying cracks in brittle materials is technically challenging and usually limited to post mortem analysis. It is therefore necessary to develop a reliable method to image the crack front shape and velocity as it propagates across a 300 mm silicon wafer at more than 2 km/s.

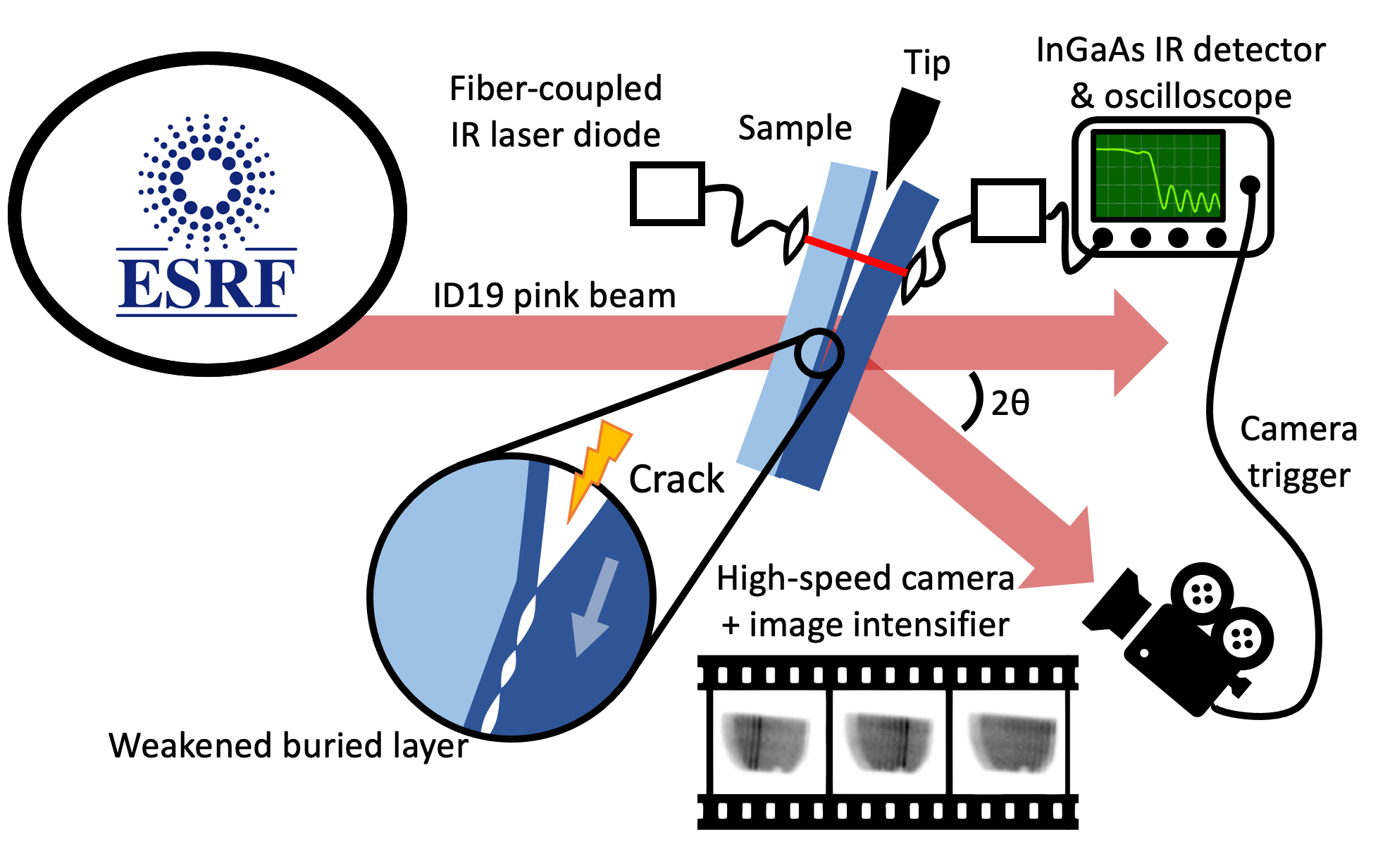

The ultra-fast camera and image intensifier at beamline ID19 were used to perform MHz X-ray diffraction imaging of the (220) or (400) crystal planes in single-crystal silicon strips or wafers. The setup is illustrated in Figure 1.

Click image to enlarge

Fig. 1: Ultra-fast imaging experiment setup used on ID19. The pink beam illuminates the bonded wafers set in Laue diffraction condition, and a high-speed camera connected to an image intensifier records the diffracted image on a scintillator. The fracture is initiated mechanically with the motorised tip. The infrared (IR) laser detects the crack and triggers the camera. The enlargement at the centre of the sample shows the propagation of the fracture through a preliminary weakened layer made by light ion implantation.

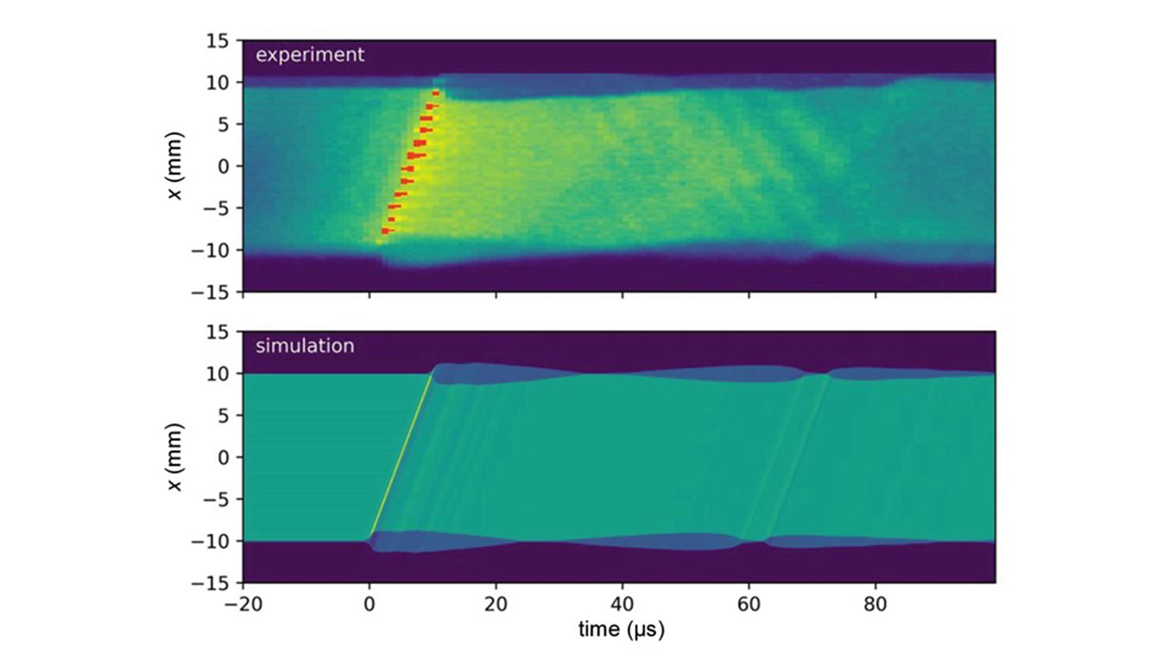

A crack was mechanically initiated to propagate in a layer preliminary weakened by light ion implantation. The change in transmission of an infrared (IR) laser was used to trigger the recording of 256 frames at up to 2 MHz image acquisition rate. The variations of the lattice tilts in the wake of the crack resulted in intensity variations in each of the sub-µs acquisition, effectively imaging the crack. The shape of the crack front – a parameter that could only be surmised in models up to now – was then observed experimentally (Figure 2). The local crack velocity at the sub-mm scale was also measured by taking advantage of the stroboscopic nature of the X-ray source. Finally, the analysis of the post-crack movements of the separated wafers provided insights into the mechanisms at play, involving pneumatic oscillations and flexural waves.

Click image to enlarge

Fig. 2: Diffracted intensity for the [110] strip sample as a function of time and position along the length x (i.e., along [110]), taken at the central y position, for (top) experimental data and (bottom) simulated data considering the propagation of the gap opening profile.

The results obtained by in-situ MHz X-ray diffraction imaging offered an otherwise unattainable vantage point on crack propagation in the SmartCut process, which is highly valuable for further finer modelling and optimisation. Correlating the results with other techniques, e.g., using visible lasers to track the movements of the reflective outer surfaces of the wafer as the crack propagates, enables a holistic description of the crack propagation mechanism. The development of the MHz X-ray diffraction imaging technique paves the way for the future development of advanced manufacturing processes for more durable and reliable materials.

The unique combination of the ultra-fast camera and visible light amplifier at ID19 makes it de facto the beamline of reference for such high-speed studies. Upcoming works will move beyond crack propagation and focus on the very early stages of crack initiation, using the thermal load of the X-ray beam on the sample to trigger the fracture inside the X-ray field of view.

Principal publication and authors

Brittle fracture studied by ultra-high-speed synchrotron X-ray diffraction imaging, A. Petit (a), S. Pokam (a), F. Mazen (a), S. Tardif (b), D. Landru (c), O. Kononchuk (c), N. Ben Mohamed (c), M. Olbinado (d), A. Rack (d), F. Rieutord (b), J. Appl. Cryst. 55, 911-918 (2022); https://doi.org/10.1107/S1600576722006537

(a) Univ. Grenoble Alpes, CEA, LETI, MINATEC Campus, Grenoble (France)

(b) Univ. Grenoble Alpes, CEA, IRIG-MEM-NRS, Grenoble (France)

(c) SOITEC, Parc Technologique des Fontaines, Bernin (France)

(d) ESRF