New in-situ test chamber for studying battery failures at ID19 using high-speed X-ray imaging

An in-situ battery test chamber has been installed at beamline ID19 to safely study, using high-speed X-ray and infrared imaging, the mechanisms that occur during battery failure caused by abuse. The robust chamber design assures safe operation, eliminating hazards related to the explosive reactions that can ensue.

Share

Energy storage is one of the key technologies of the 21st century. The increasing number of electric vehicles, the need to reduce carbon emissions and to effectively store energy from renewable sources are just some of the challenges we face today. Improving battery technology is thus critical to deal with these challenges. This requires a deep understanding of battery reliability and safety issues, such as the internal processes that occur during battery failure caused by abuse to the cell. Mechanical abuse, thermal abuse, incorrect charging or internal/external short circuit of a battery can lead to highly energetic and rapid failures (called thermal runaway, or TR) that may even, in rare cases, result in an explosion.

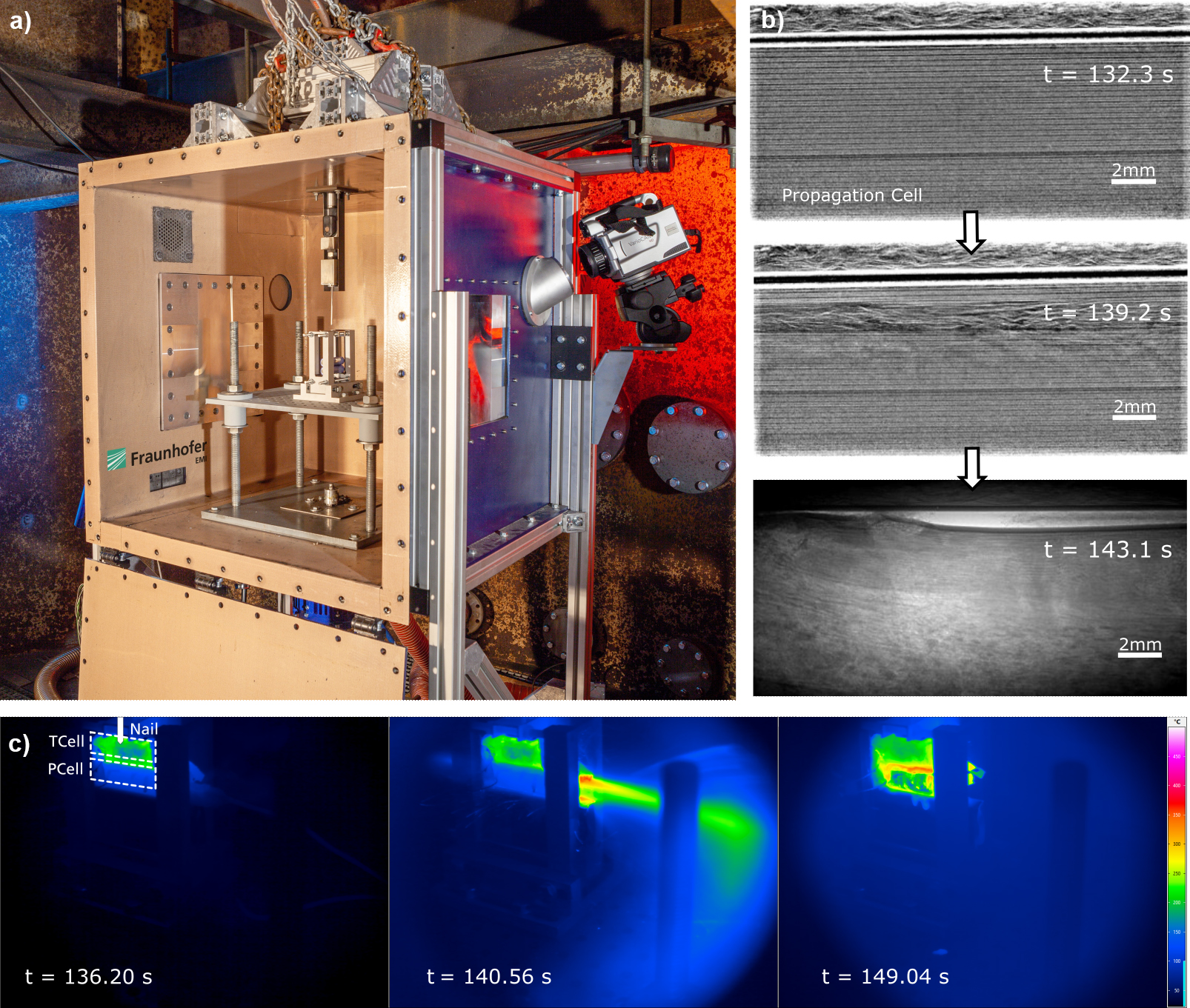

To understand the entire chain of processes leading from a single, localised fault in a battery cell to TR, a combination of experimental techniques is needed to provide data that span a large variety of time and length scales. In order to carry out such experiments safely, a suitably prepared and safe laboratory environment that is able to handle the expected dangers as well as allow precise measurements is required. In this context, Fraunhofer Ernst Mach Institute has developed a robust experimental battery-abuse test chamber that safely contains the TR event (Figure 1a). The chamber, now installed at ESRF microtomography beamline ID19, allows researchers to study the processes involved in TR using different measurement methods, including temperature, infrared imaging, and high-speed X-ray imaging, in a routine manner.

Click image to enlarge

Fig. 1: a) The test chamber. b) Snapshots from high-speed X-ray video and (c) thermography acquisitions of a lithium-ion battery. Thermal runaway (TR) was induced through TR propagation from an adjacent cell triggered by nail penetration. The X-ray images show the process of gas formation and layer deformation. The thermographic images visualise the spatially resolved heat dissipation and the venting process during TR.

In order to test the chamber, high-speed X-ray imaging was carried out at beamline ID19 to enable the in-situ visualisation of rapid failure mechanisms of high-energy lithium-ion batteries, including the formation of gas accumulations with associated structural collapse and material degradation (Figure 1b and c). The design of the chamber, and the possibility to implement multiple additional measurement sensors, including temperature, voltage and thermography, facilitated the correlation of various processes as well as the ability to draw comprehensive conclusions. The chamber can tolerate fire and a significant increase in pressure, and can dissipate any toxic gas and particles via a filtration system. This enables a wide range of different cell types and formats to be studied at ID19 within the frame of the public user programme (academic and industrial).

The new test chamber at ID19 serves as a complement to standardised safety tests and will aid researchers and manufacturers to better understand the spatio-temporal dynamics of battery failure, to evaluate safety mechanisms and to validate existing and new TR models. The flexible and comprehensive design will enable a multi-physics approach to deepen the understanding of the internal processes involved in battery failures. Possible use cases include the study of cell-to-cell propagation and the ejection process during TR. The established and comprehensive safety protocol, combined with the effective and user-friendly application, will help to advance battery safety research at the ESRF and to make high-speed X-ray investigations of battery failure accessible to a wide range of academic and industrial users, further improving the safety of battery modules and cells.

Principal publication and authors

In situ chamber for studying battery failure using high-speed synchrotron radiography, J. Pfaff (a), M. Fransson (b,c), L. Broche (b), M. Buckwell (c,d), D.P. Finegan (e), S. Moser (a), S. Schopferer (a), S. Nau (a), P.R. Shearing (c,d), A. Rack (b), J. Synchrotron Radiat. 30, 192-199 (2023); https://doi.org/10.1107/S1600577522010244

(a) Fraunhofer Institute for High-Speed Dynamics, Ernst-Mach-Institut, EMI (Germany)

(b) ESRF

(c) Electrochemical Innovation Laboratory, Department of Chemical Engineering, University College London (UK)

(d) The Faraday Institution, Harwell Science and Innovation Campus (UK)

(e) National Renewable Energy Laboratory (USA)