- Home

- News

- Spotlight on Science

- Probing the structure...

Probing the structure of bagworm silk with scanning X-ray nanodiffraction

06-04-2023

Bagworm silk is a fascinating natural protein fibre with extraordinarily strong and tough mechanical properties. Using the 250 nm X-ray nanobeam at beamline ID13, a single bagworm silk fibre was divided into 20 virtual parts across the diameter, revealing a gradient heterogeneous fibrillar structure.

Global ecological damage has heightened the demand for materials made from sustainable resources. The quest to develop materials with specific properties requires a deep understanding of the relation of a material’s structure at the microscopic scale to its functional properties. Indeed, the high toughness (or exceptional blend of strength and elasticity) of spider dragline silks shows promising potential for the next generation of structural materials, and biomimetic artificial silks produced by gene-recombinant techniques could be a replacement for petroleum-based materials across a range of industries, from structural materials to textiles, or used in biomedical applications such as tissue engineering. However, producing artificial silks with comparable mechanical properties to natural silks requires a further deepening of our understanding of the structure-property relationships in silk proteins [1]. In addition, the low crystallinity of spider or silkworm silks makes progress in such structural studies difficult.

A team of researchers from the Silk Materials Research Group of the Japanese National Agriculture and Food Research Organization (NARO) studying a silk produced by the larvae of Japan’s largest bagworm moth, Eumeta variegata (Lepidoptera: Psychidae), have identified an extraordinarily strong and tough mechanical property of bagworm silk, parallel to the spider dragline silks [2].

In previous work, the researchers conducted a study on the structure–property relationship in bagworm silk by carrying out in-situ X-ray diffraction measurements of the fibre bundle (Figure 1a) during its stretching deformation. The data revealed that the outstanding mechanical properties of bagworm silk are the result of a highly ordered hierarchical structure based on fibroin protein, which remains unchanged until fracture. The results provide unique insights into the relation of microstructure to the functional properties of silks.

Click figure to enlarge

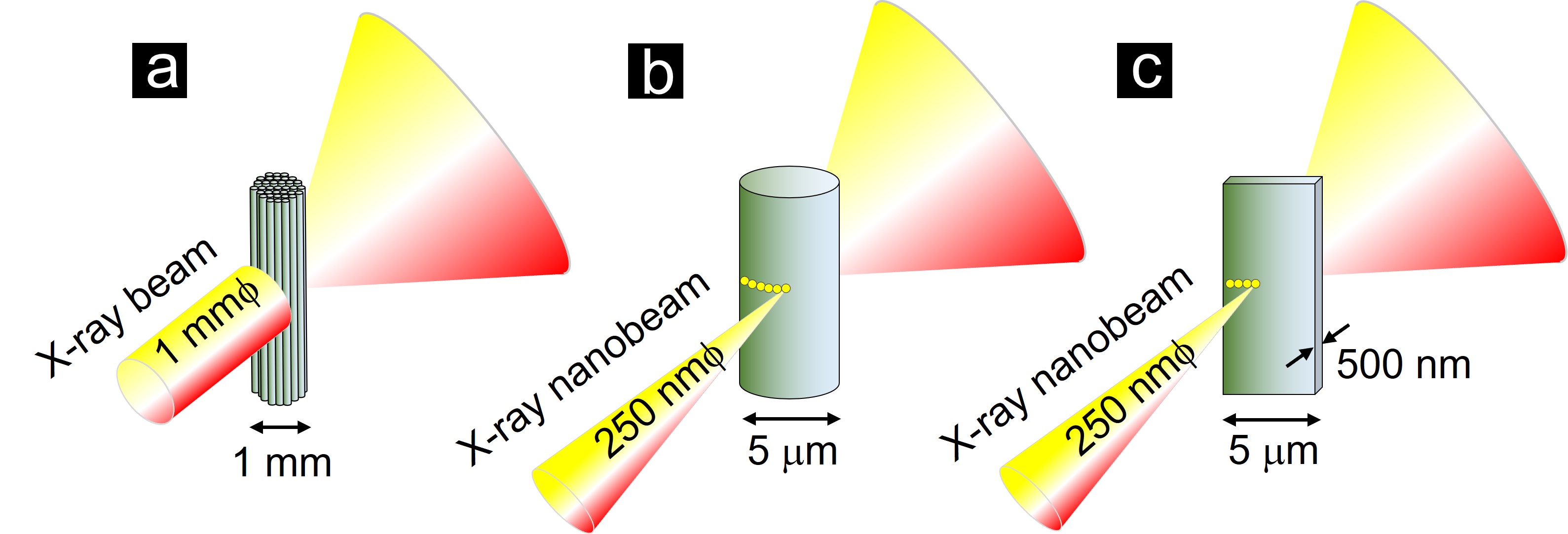

Fig. 1: Schematic depictions for the different experimental geometries of X-ray measurements on bagworm silk. a) Geometry used previously by the NARO group, in which a fibre bundle was probed by a conventional X-ray beam with a diameter of ca. 1 mm [2]. b-c) Geometries used in this study utilising a scanning X-ray nanobeam with a diameter of 250 nm for (b) a single thread with a diameter of 5 mm and (c) a 500-nanometre-thick section of single thread (sectioned along the fibre axis).

In this work, the homogeneity of the hierarchical structural organisation of single bagworm fibres of ~5 microns in diameter was investigated using scanning X-ray scattering at beamline ID13 to probe the whole fibre diameter (Figure 1b and 2a-b). ID13 provides a 250 nm X-ray scattering probe covering the small- to wide-angle X-ray scattering range [3], making it possible to probe down to sub-micrometre fibre sections, and thus avoiding scattering from the sericin coat layer masking weak fibroin scattering (Figure 1c).

Click figure to enlarge

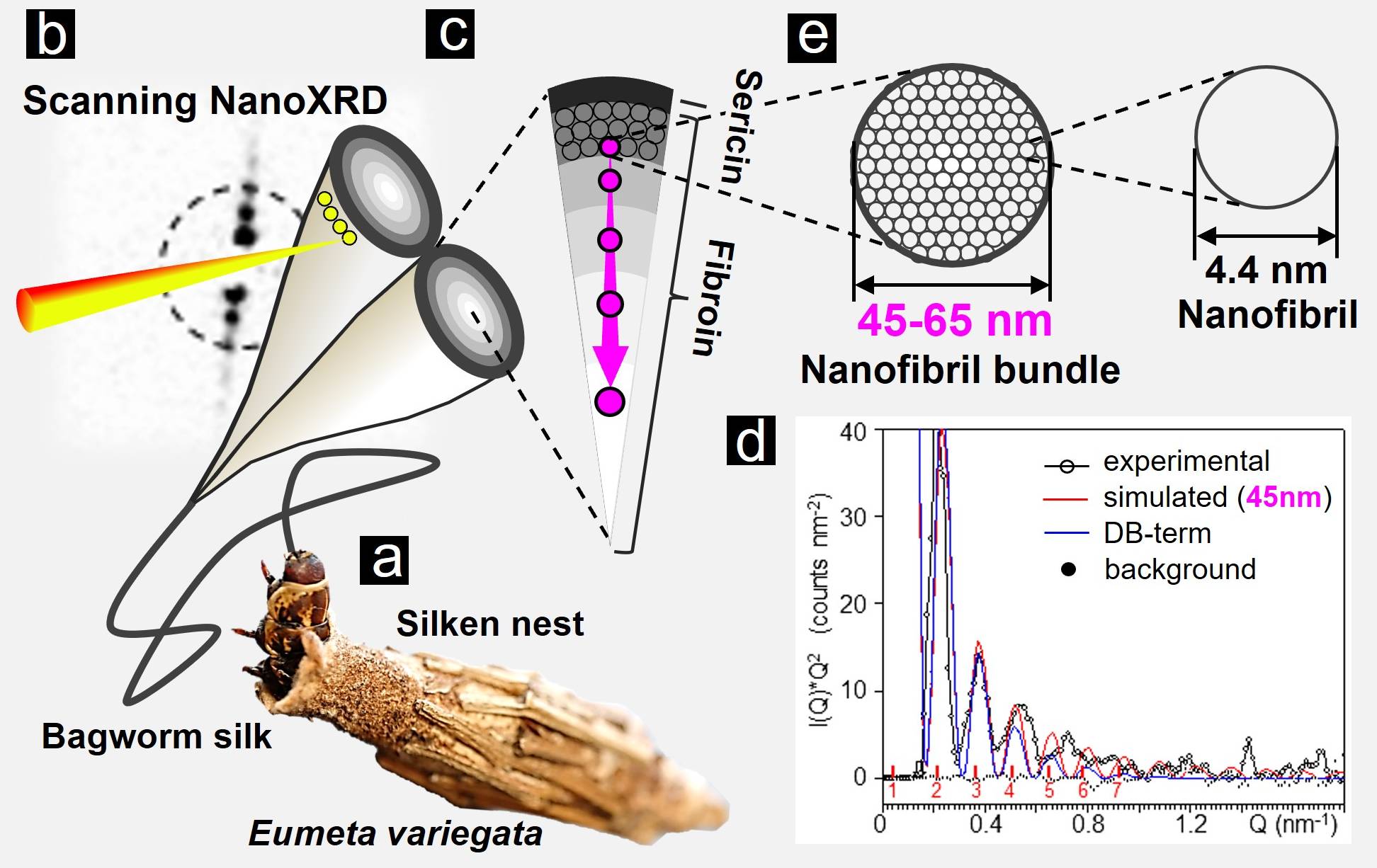

Fig. 2: Exploring the hierarchical structural organisation of bagworm silk using scanning X-ray nanobeam scattering at beamline ID13. a) Bagworms (Eumeta variegata) produce a strong and tough silk thread made of a pair of sericin-coated fibroin protein fibres, which are (b) scanned through a ~250 nm X-ray beam, (c) revealing a layered morphology consisting of a fibroin core and two skin layers composed of fibroin and sericin proteins. d) The fibroin small-angle X-ray scattering from the skin layer and the core was simulated by a cylindrical form factor for nanofibrillar bundles with diameters from 45 to 65 nm (red curve). A Debye-Waller (DB) factor was applied to simulate a rough bundles interface (blue curve). e) Higher-order assembly into bundles of closely packed nanofibrils of about 4.4 nm separation is observed in the sub-micron skin layer, decreasing in density in the core.

Using this technique, the researchers were able to visualise the homogeneous distribution of fibroin nanofibrils in the silk fibres. The higher-order assembly of nanofibrils into bundles of 45 nm to 65 nm diameter, increasing gradually in diameter from the outer skin layer to the inner core, was found to be particularly strong in the skin layer, decreasing strongly in concentration in the core (Figure 2c). The modulated equatorial fibroin scattering extending from the skin layer to the inner core was attributed to nanofibrillar bundles and simulated by form factor scattering from cylinders with diameters from 45 nm to 65 nm (Figure 2d). The close packing of nanofibrils allowed the researchers to directly determine their average separation as about 4.4 nm (Figure 2e).

Dragline-type silks are frequently pictured as a network of protein chains reinforced by crystalline nanodomains. Higher-order assembly into nanofibrillar morphologies is generally assumed, and modelling suggests its importance for mechanical properties in spider dragline silks. Recent modelling studies predicted the formation of mesoscale (> 50 nm) assembly, required for critical mechanical performance [4]. This study not only experimentally demonstrates the modelling prediction, but also reveals a gradient heterogeneous fibrillar structure, which has not been previously detected using a conventional X-ray beam or even an X-ray nanobeam for the unsectioned single thread with sericin coating. These results open up new possibilities for bottom-up modelling approaches of the mechanical properties of silk and for developing structural control techniques in artificial silk spinning.

Principal publication and authors

Mesoscale Confinement in Bagworm Silk: A Hidden Structural Organization, T. Yoshioka (a), T. Kameda (a), M. Burghammer (b), C. Riekel (b), Nano Lett. 23, 3, 827-834 (2023); https://doi.org/10.1021/acs.nanolett.2c03734

(a) Silk Materials Research Group, National Agriculture and Food Research Organization (Japan)

(b) ESRF

References

[1] K. Bourzac, Nature 519, S4-6 (2015).

[2] T. Yoshioka et al., Nat. Commun. 10, 1469 (2019).

[3] C. Riekel et al., Biomacromolecules 18, 231-241 (2017).

[4] T. Giesa et al., Nano Lett. 11, 5038-5046 (2011).

| About the beamline: ID13 |

|

ID13 is dedicated to high-spatial-resolution diffraction and scattering experiments using focused monochromatic X-ray beams. Two end-stations: a microbranch and a nanobranch, are operated in serial mode. The principal aim is to provide small focal spots for diffraction and small-angle X-ray scattering (SAXS). Both single-crystal and scanning diffraction experiments are performed. Other applications, like scanning X-ray microfluorescence, are feasible. A broad range of materials can be examined, from bio- and synthetic polymers to composites and minerals. The current setups allow for the study of single crystals (including proteins), fibres or extended samples. Specific sample environments are also available, including stretching cells, micro-grazing-incidence small-angle X-ray scattering (GISAXS) and microfluidics (utilising both mixing-cell and microdroplet technologies). |