- Home

- News

- Spotlight on Science

- Ultra-fast X-ray...

Ultra-fast X-ray imaging of keyhole dynamics during laser 3D printing

09-09-2020

Laser 3D printing enables fabrication of complex components by melting powder with a laser beam in a few milli-seconds, forming non-equilibrium structures. Beamline ID19’s ultra-fast X-ray imaging captures the mechanisms of microstructure formation, shedding new light on 3D printing.

Laser powder bed fusion (LPBF) is a form of laser 3D printing that enables the fabrication of metallic components with complex geometry that cannot be produced via other manufacturing techniques. The printing process is very complex as it involves laser-matter interaction, multiphase flow, and solidification phenomena, all occurring in 10-3 to 10-6 s. The time-scale at which these events take place makes it difficult to study the underlying physics to predict and control the manufacturing process and product quality.

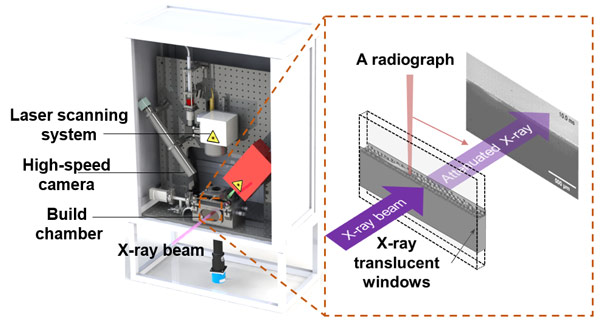

A laser 3D printing machine that works on a synchrotron beamline, a.k.a. the In situ and operando process replicator (ISOPR, see Figure 1), has been built to study these ultra-fast dynamics using synchrotron X-ray imaging and diffraction. ISOPR consists of a 200 W laser beam with a scan speed of 4 m/s, and the capability to perform complex multi-layer builds. It enables researchers and industrial collaborators to perform 3D printing at a synchrotron beamline whilst monitoring its process dynamics in situ and operando. With beamline ID19’s high-flux and high-brilliance X-rays, ultra-fast imaging was used to unravel and elucidate the phenomena that control the formation of imperfection during laser printing. As the experiments involved complex laser, powder, and X-ray safety aspects, support from ID19’s beamline scientists and ESRF’s technical teams contributed significantly.

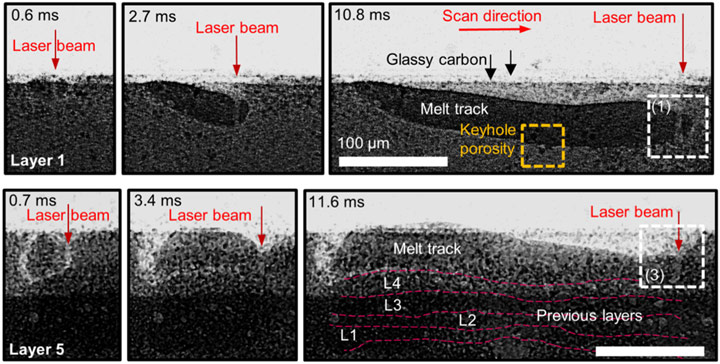

The melt pool dynamics during keyhole mode operation was investigated, including its relationship with porosity and spatter formation mechanisms in Ti-6Al-4-V (see Figure 2). The melt pool was observed to change in a cyclic manner with a transient separation of the portion of the melt pool in front of the laser beam. How this cyclical process is related to the formation of microstructural features was elucidated, in particular for keyhole porosity and spatter, which are potentially detrimental to the mechanical performance of the final 3D printed components.

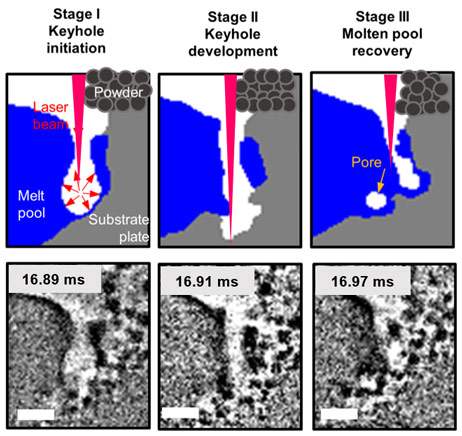

The evolution of a multi-layer melt track during LPBF was examined and it was found that the keyhole undergoes a transient cyclic phenomenon where a vapor depression zone is created, changing the keyhole pressure, and altering its shape by Marangoni convection. This mechanism can be summarised in three stages (see Figure 3): (1) keyhole initiation – the formation of a vapor depression zone due to the laser-induced metal vaporisation; (2) keyhole development - wherein the powder is being entrained into the laser-matter interaction zone and then promotes the formation of droplet spatter, and (3) the molten pool recovery – change in pressure causes the keyhole to re-open.

|

|

Figure 3. Schematic showing the three stages of cyclic melt pool dynamics, which are summarised as (I) keyhole initiation, (II) keyhole development, and (III) molten pool recovery. |

From this study, it was also found that the keyhole porosity tends to form in stages 2 and 3 described in the cyclic event where a pore is formed when the fast-moving metal vapor pushes the molten liquid around it. Besides this, the cyclic oscillation of the keyhole also promotes spatter ejected from the laser-matter interaction zone, the high-speed X-ray images revealed how the droplet is formed by the agglomeration of powder particles at stage II of the cyclic event.

The benefits of this work included a clarification of the physical understanding behind the keyhole mode LPBF. These new insights can be coupled with modelling to improve the quality of LPBF built components. The mechanisms observed and the understanding gained from this study can be transferrable to other beam-based processing techniques, such as laser/electron beam welding and other forms of powder bed fusion additive manufacturing where keyhole mode porosity and excessive spatter need to be avoided.

Principal publication and authors

In-situ synchrotron imaging of keyhole mode multi-layer laser powder bed fusion additive manufacturing, Y. Chen (a,b), S.J.Clark (a,b), C.L.A. Leung (a,b), L. Sinclair (a,b), S. Marussi (a,b), M.P. Olbinado (c), E. Boller (c), A. Rack (c), I. Todd (d), P.D. Lee (a,b), Appl. Mater. Today 20, 100650 (2020); DOI: 10.1016/j.apmt.2020.100650.

(a) UCL Mechanical Engineering, University College London (UK)

(b) Research Complex at Harwell, Rutherford Appleton Laboratory, Didcot (UK)

(c) ESRF

(d) Department of Materials Science and Engineering, University of Sheffield (UK)