- Home

- News

- Industry news

- New standard for...

New standard for residual stress measurement in metals

15-05-2025

The EASI-STRESS project – a collaboration between research institutions and industry – has resulted in the first formal technical specification for non-destructive residual stress measurement in metals using synchrotron X-ray diffraction. This standardized approach enables reliable and reproducible stress analysis, supporting safer, more efficient, and better-performing metal component design and manufacturing.

Share

Residual stress characterization is vital for the safety and performance of critical industrial components, from automotive parts to aerospace structures. Traditional measurement methods are often destructive or restricted to surface-level analysis. In contrast, synchrotron and neutron techniques provide unique, non-destructive access to full stress tensors deep within materials.

High resolution stress mapping allows researchers and engineers to trace the origins and evolution of residual stresses throughout manufacturing and service life, enabling informed strategies for their mitigation or use. This understanding supports design optimization, prolongs component lifetimes, and reduces material waste.

To enable industry to benefit from these advanced techniques, formalized guidelines for calibration, data acquisition, and analysis are essential to ensure reproducibility and reliability across facilities.

The EASI-STRESS project, a collaboration among the ESRF, the ILL, and the Danish Technological Institute, and other partners, funded by the European Union’s Horizon 2020 programme, has addressed this need by establishing standardized procedures for synchrotron X-ray diffraction-based residual stress measurements.

Project partners developed harmonized protocols and data formats, incorporating input from both research organizations and industrial stakeholders to ensure interoperability and traceability across institutions [1]. The resulting technical specification, issued as a pre-standard (DIN CEN/TS 18094:2025-02), was developed in collaboration with a recognized standardization body [2].

These efforts aim to reduce entry barriers and support broader industrial adoption of large-scale facility-based techniques by reducing variability, improving consistency and uniformity in products and processes, and enabling efficient use of beamtime and resources.

To further support adoption, dedicated software tools were also developed to streamline data analysis and reduce the technical expertise required for data interpretation [3,4]. These tools enable seamless integration of experimental data with computational models, a key capability for maximizing the utility of residual stress data in engineering applications.

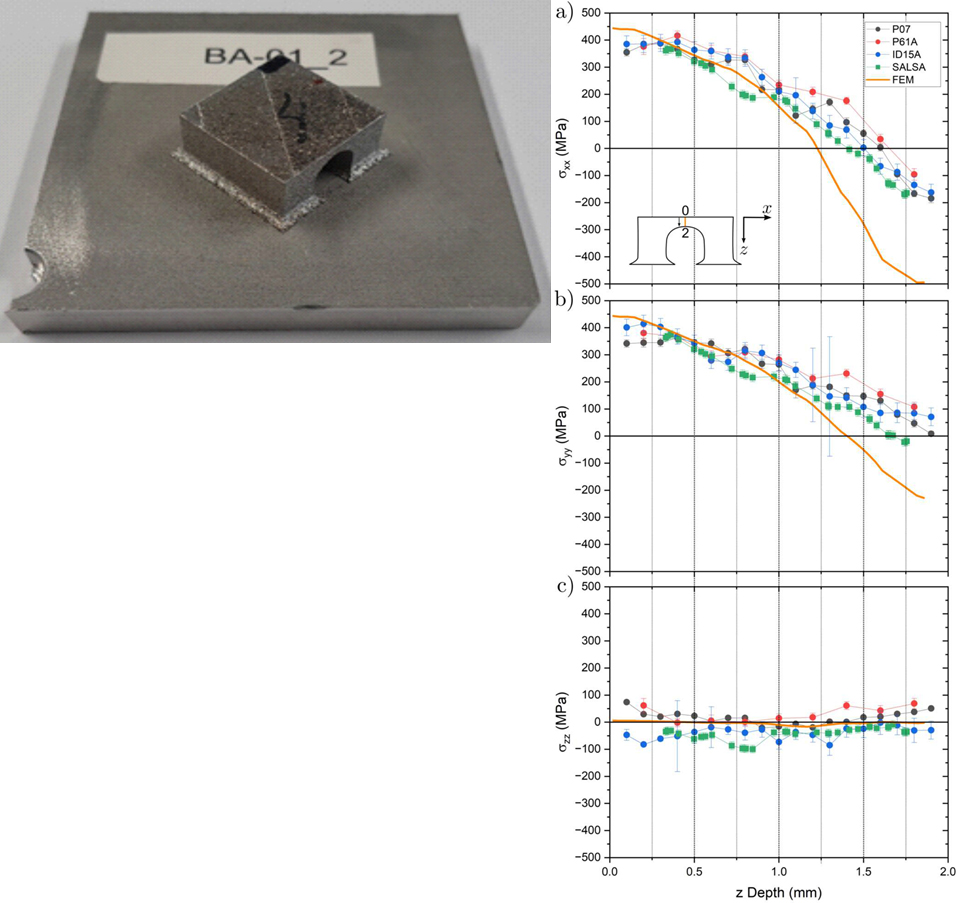

The benefits of large-scale facility-based residual stress analysis in metals were demonstrated through benchmark studies conducted within the EASI-STRESS project. In one such study, laser powder bed fusion (LPBF) was used to produce additively manufactured (AM) arches from 316L stainless steel powder (Figure 1, left).

As the most common metal AM technique, LPBF typically introduces significant residual stresses due to repeated, localized high-gradient thermal cycles during laser scanning. The residual stresses in these arches were measured using four different beamline strain scanners, including synchrotron X-ray diffraction at ESRF’s beamline ID15A (Figure 1, right), DESY’s P07 and P61A beamlines, and neutron diffraction at the SALSA instrument at ILL [5,6]. These comparative studies validated the newly developed protocols and software, while also benchmarking synchrotron-based techniques against other surface and destructive testing methods used across facilities.

Click figure to enlarge

Fig. 1: Left: A photograph of an example stainless steel arch additively manufactured using LPBF. Right: Residual stress components along Line 1 (measured from the top surface to the apex of the arch, shown by orange line in inset) in (a) x-, (b) y-, and (c) z-directions. Results are shown from four diffraction-based scanning instruments: synchrotron X-ray diffraction from the ESRF’s ID15A beamline (blue), and DESY’s P07 (black) and P61A (red) beamlines, and neutron diffraction from the SALSA instrument at ILL (green). Predicted values from the inherent strain finite element model are shown in orange. Error bars represent uncertainties propagated from peak fitting only.

The standardization efforts of the EASI-STRESS project pave the way for industrial exploitation of residual stress analysis at large-scale facilities by enhancing both precision and operational efficiency. Adoption of the new standard will enable industry to better manage residual stresses in metallic components, leading to longer service lifetimes, reduced maintenance and production costs, and optimized designs.

Furthermore, the availability of standardized, user-friendly methodologies is expected to accelerate innovation across sectors, from aerospace to energy, by facilitating deeper insight into stress evolution during manufacturing and service.

The EASI-STRESS project demonstrates how the advanced analytical capabilities of large-scale facilities can be made accessible and impactful for industrial applications, reinforcing Europe’s leadership in non-destructive testing and materials innovation on the global stage.

References

[1] https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5e66eb589&appId=PPGMS

[2] https://www.dinmedia.de/en/pre-standard/din-cen-ts-18094/386725050

[3] https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5fa81c427&appId=PPGMS

[4] https://github.com/aapaecklar/SOFT-AIS

[5] R.C. Laurence et al., Strain 61, 2 (2025).

[6] https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5f6c6af01&appId=PPGMS

Top image: Nikolaj Gersager Henriksen, Senior Consultant, Danish Technological Institute. For more information, please contact: nigh@teknologisk.dk, +45 72 20 24 84, www.dti.dk