- Home

- Industry

- Applications and case studies

- Consumer products

Consumer products

Goods for everyday use are constantly being developed by manufacturers. Innovation is the name of the game for the development of consumer products. Longer shelf life, better performance and lower production costs make an item more appealing for the consumer. The ESRF has a role to play.

Developing new cosmetic or cleaning products demands high-performance characterisation tools that allow researchers to visualise complex nanostructured materials across all relevant length scales. Synchrotron X-rays offer a complementary technique to electron microscopy that provides in-depth information about the rheology and stability of products and allows studies of the body’s tolerance to new product formulations.

Foods are also complex mixtures of components with diverse thermal, mechanical, rheological and ageing properties. Synchrotron techniques allow researchers to correlate the macroscopic properties of a sample with its microstructure, helping companies meet consumer demand for nutritional value, novelty and ease of use, across products ranging from bread to butter.

- Study the microstructure of consumer goods for their improvement.

- Studying real product behavior in different sample environments.

- Analysis of materials in real in situ processes simulating industrial processing conditions.

- Detect trace elements and map molecular groups and structures on the nanoscale using infrared spectroscopy.

CASE STUDIES

|

Company

Unilever

Challenge

Hair conditioners are based on a dispersion of liquid crystalline phases that work with the flow of water to lubricate and protect hair fibres. The stability of such products is vital for guaranteeing consistent performance. The validation of stability can be done with characterisation techniques that measure physical properties of the bulk product, such as rheology, pH, light scattering and calorimetry. However, it is difficult to understand what and how underlying microstructures influence the bulk properties and any changes that occur over time.

Sample

Ingredients of conditioner products and their permutations.

Solution

The team used small angle X-ray scattering at ID02 to monitor the microstructure evolution of the products at critical intervals during a three-month trial.

Benefits

The experiment proved instrumental in providing a mechanistic understanding of how a hair conditioner microstructure evolves with the passage of time, from factory to consumer.

CompanyProcter & Gamble (P&G) Challenge As much as 90% of the energy used to wash clothes goes towards heating the water in washing machines, so one of the main goals for companies like P&G is to develop detergents that work at lower temperatures. The majority of liquid detergent formulations exist as micellar solutions to ensure easy dosing and fast dissolution, but this requires the formula to have a high water content. If the water content is reduced, liquid crystals will start to form unless organic solvent is added, which adds more to the cost of a product and dents its environmental credentials. Another approach is to formulate it as liquid crystal, but the presence of other ions typically destabilises the product and causes “phase splits”. Sample Anionic surfactants, enzymes, polymers. Solution Researchers at P&G want to have a better knowledge of the microstructure of the colloidal formulations in order to tune the performance and stability of products, and meet the company´s environmental sustainability targets. Small Angle X-ray Scattering was used to map the phase diagram of Ariel Excel Gel to determine the regions that are physically stable within the formulation space of interest. Benefits Ariel Excel Gel, boasts cleaning at 15 °C thanks to specially designed enzymes and polymers, offering considerable energy savings. It is also highly concentrated, requiring less water to manufacture and reducing transport and storage costs. It has become the first liquid detergent with a liquid-crystal microstructure with the lowest water content possible without the use of organic solvent. |

|

Company

Unilever

Challenge

Freeze-dried vegetables form the basis of many instant foods such as soups and sauces. Unilever wanted to optimise the freeze-drying and rehydration process to produce products with higher quality flavours and textures and with better convenience for the customer. They came to the ESRF to study the effect of different freeze-drying conditions on the microstructure of carrots. Having already carried out extensive characterisation of freeze-dried carrots using techniques that included SEM, MRI, NMR and laboratory source X-ray microtomography (µCT), the aim of the synchrotron experiments was to provide quantitative data through high-resolution 3-D µCT imaging.

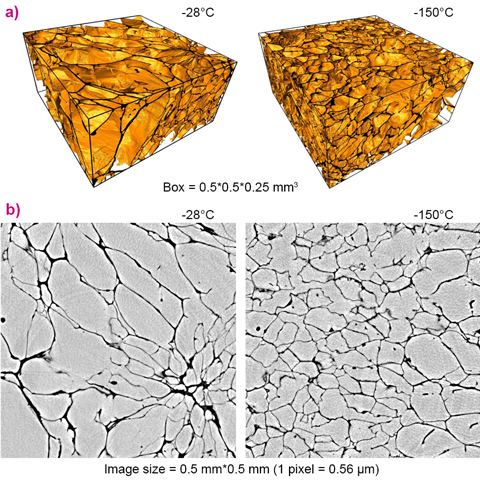

Sample

Samples were cylinders cut from the cortical tissue of winter carrots (sample dimensions were typically 10 mm by 6 mm). Pre-treatment to freeze-drying included blanching for one minute in boiling water. Freeze-drying was carried out at various temperatures between -28°C and -150°C.

Solution

High-resolution micro computed tomography was used at beamline ID19 providing non-destructive imaging with sub-micrometre resolution. Synchrotron scans are faster than conventional CT, typically a few minutes compared to hours for conventional CT, which leads to less motion artefacts for evolving samples and the corresponding image quality is much better through its better signal to noise ratio. Boundaries between regions of different density can be enhanced with phase-contrast imaging. Using 3-D models of the data, segmentation can be used to isolate and reveal regions of similar absorption, i.e. density, which can be used for an accurate estimate of the volume of components.

a) 3-D X-ray tomography imaging of freeze-dried carrot for blanched samples frozen at -28°C and -150°C. b) Representative cross sections of the 3D tomography images. Image credit: G. van Dalen, Unilever.

Benefits

For dehydrated carrot, image analysis of the 3D data sets permitted determination of the size (distribution) of the cell wall thickness and pore diameter. In rehydration experiments, it was possible to visualise rehydration of a sample over a time period of many hours.

The experiments revealed that freeze-drying at lower temperatures produces dehydrated carrots with smaller and more homogenous granular structures, which translates to improved textures in rehydrated material. Furthermore, the blanching pre-treatment produces dehydrated carrot samples with significantly thinner cell walls than non-blanched samples, which helps explain why they rehydrate faster leading to a better texture and appearance for the customer.

References

Conference papers:

Multi-length scale structural imaging of freeze-dried carrots and their rehydration behaviour, Gerard van Dalen, Adrian Voda, Arno Duijster, Lucas van Vliet, Frank Vergeldtd, Ruud van der Sman, Henk Van As, John van Duynhoven (2013), InsideFood Symposium, 9-12 April 2013, Leuven, Belgium.

Study of the water vapour sorption of freeze dried carrots using micro-CT, Martin Koster, Gerard van Dalen, InsideFood Symposium, 9-12 April 2013, Leuven, Belgium.

Publications:

Rehydration kinetics of freeze-dried carrots, F.J. Vergeldt, G. van Dalen, A.J. Duijster, A. Voda, S. Khalloufi, L.J. van Vliet, H. Van As, J.P.M. van Duynhoven, R.G.M. van der Sman, Innovative Food Science and Emerging Technologies 24 (2014) 40–47; doi: 10.1016/j.ifset.2013.12.002.

Multiphysics pore-scale model for the rehydration of porous foods, R.G.M. van der Sman, F.J. Vergeldt, H. Van As, G. van Dalen, A. Voda, J.P.M. van Duynhoven, Innovative Food Science & Emerging Technologies 24, 2014, 69-79; doi: 10.1016/j.ifset.2013.11.008.