- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2012

- Dynamics and extreme conditions

- Exploring the formation of nanocrystallites

Exploring the formation of nanocrystallites

Iron-containing metallic glasses exhibit unique soft magnetic properties that are attractive for a variety of practical applications including transformer cores, magnetic sensors and magnetic shielding. The beneficial magnetic parameters are closely related to the amorphous state of the material. However, their prolonged operation at elevated temperatures leads to a partial crystallisation which produces a deterioration of the advanced magnetic features.

Nanocrystalline alloys represent a new class of materials that offer a rich variety of new physical properties. They can be tailored by tuning the chemical and structural compositions by controlling the size and morphology of the crystalline nanograins. These nanocrystalline materials are prepared by controlled crystallisation of metallic glasses at defined conditions (temperature, time). The presence of nanocrystalline grains embedded in the residual amorphous matrix stabilises the structure, preserving and even enhancing the performance of these materials.

The transformation of the structure via crystallisation is one of the mechanisms that considerably affects the macroscopic physical properties of these materials. In order to further optimise these properties, it is necessary to understand the microstructure and the processes that are taking place during the crystallisation. The behaviour of metallic glasses is usually investigated under static external conditions in relatively long time windows over several tens of minutes. In contrast, the information derived by rapid data acquisition techniques is averaged over the entire volume of the sample and is limited only to one specific feature such as structural order or magnetic behaviour. Therefore, further elucidation of the nanocrystallisation kinetics requires a thorough understanding of the nanograin growth by disentangling the evolution of structurally different components, i.e. nanograins, interfaces, and the residual amorphous precursor, that takes place during thermal annealing. To reach this goal we have used the method of nuclear forward scattering (NFS) at the Nuclear Resonance Station ID22N. Choosing iron atoms as probes, information on their magnetic states (hyperfine interactions), consequently on the structural arrangements, is simultaneously obtained. The high brilliance of third-generation synchrotron radiation sources allows NFS spectra to be collected with sufficiently high statistics for very short time intervals. This made in situ monitoring possible for the temperature driven process of crystallisation demonstrated in this work.

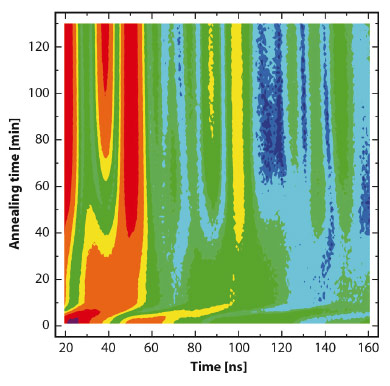

The time spectra of nuclear forward scattering were collected during isothermal heat treatment at a temperature close to the onset of crystallisation of the investigated NANOPERM alloy. The obtained NFS spectra reveal rapid development that takes place shortly after the beginning of the annealing process (Figure 45). This is a direct consequence of the changes in the hyperfine interactions due to modifications of the nearest neighbourhood of the iron atoms connected with the emerging ferromagnetic nanocrystalline grains.

|

|

Fig. 45: Contour plot of the NFS spectra showing the appearance of magnetic hyperfine interactions after about 45 minutes of annealing. Note also progressive changes in the spectra immediately after the beginning of the heat treatment. |

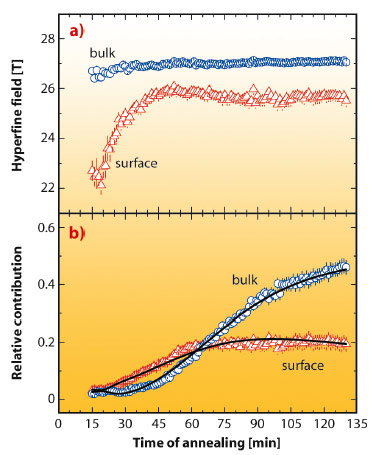

By performing a quantitative analysis of the NFS spectra (Figure 46) we were able to disclose the nucleation and growth of the iron nanograins to fine details by accessing separately atoms located in their interior (bulk), at their surfaces as well as those that belong to the residual amorphous matrix. The crystallisation model we developed (solid lines in Figure 46b) gave complete explanation of the experimental data (open symbols in Figure 46b).

|

|

Fig. 46: Magnetic hyperfine fields (a) corresponding to the bulk and surface iron atoms in the newly born nanocrystals are stabilised once their structure is well developed. During this grain growth process, the relative contribution of the surface atoms dominates that of the bulk atoms, which appears later (b). |

By using NFS experiments, it is now possible to identify the interface regions formed by the atoms located at the surfaces of the nanograins. The interface component in the NFS spectra prevails at the stages of early crystallisation when the majority of atoms are located at the nanograin surface. At advanced crystallisation stages, the bulk fraction, resulting from the growth of the nanograins size as well as of their number, increases.

Employing in situ nuclear forward scattering during isothermal crystallisation, the process of nanograin formation was investigated in real time revealing how the nanograins are formed, especially at the very early stages of isothermal annealing. Even though the overall formation of nanocrystals can also be deduced from other analytical techniques, our approach provides the possibility to study independently iron atoms positioned at different structural sites within the alloy owing to their site-specific hyperfine interactions.

Principal publication and authors

M. Miglierini (a,b), V. Prochazka (b), S. Stankov (c,d), P. Svec, Sr. (e), M. Zajac (f), J. Kohout (g), A. Lancok (h), D. Janickovic (e) and P. Svec (e), Phys Rev B 86, 020202(R) (2012).

(a) Slovak University of Technology in Bratislava (Slovakia)

(b) RCPTM, Palacky University (Czech Republic)

(c) Institute for Synchrotron Radiation, Karlsruhe Institute of Technology (Germany)

(d) Laboratory for Applications of Synchrotron Radiation, Karlsruhe Institute of Technology (Germany)

(e) Institute of Physics, Slovak Academy of Sciences (Slovakia)

(f) ESRF

(g) Charles University (Czech Republic)

(h) Institute of Inorganic Chemistry, AS CR (Czech Republic)