EH2 - Surface X-Ray Diffraction and Hard X-Ray Photoelectron Spectroscopy (SXD+HAXPES)

SXRD + HAXPES Surface X-ray Diffraction and Hard X-ray photoelectron spectroscopy

The SXRD+HAXPES station hosts a state-of-the-art set-up dedicated to the simultaneous combination of X-ray Diffraction and Hard/Soft X-ray Photoelectron Spectroscopy. Such a set-up offers the unique possibility to correlate the atomic structure (crystallinity) with its compositional, chemical and electronic properties under same experimental condition and on the same sample. This is of particular importance for many systems, such as complex oxides or topological insulators, i.e., strongly correlated electron systems, for which their macroscopic properties are intimately related to an intricate interplay between charges, spin, and lattice degrees of freedom. In addition, the combination of X-ray reflectivity with hard and soft X-ray photoelectron spectroscopy is crucial for retrieving an accurate non-destructive compositional and electronic depth profile in the tens of nanometres depth-scale with nanometre resolution in amorphous, polycrystalline, single crystalline samples or hetero-structures. Even more, the ability to tune the excitation energy in the hard X-ray regime enables tuning the sampling depth, i.e. depth profile analysis, but also enables the discrimination between bulk and surface effects, especially if combined with variable incident angle and with soft x-ray excitation. Such a combination of techniques finds its optimal use in-situ experiments, .i.e., in-situ growth or in-situ treatment, as it is the only possibility to guaranty an accurate correlation between structural, compositional, chemical and electronic properties.

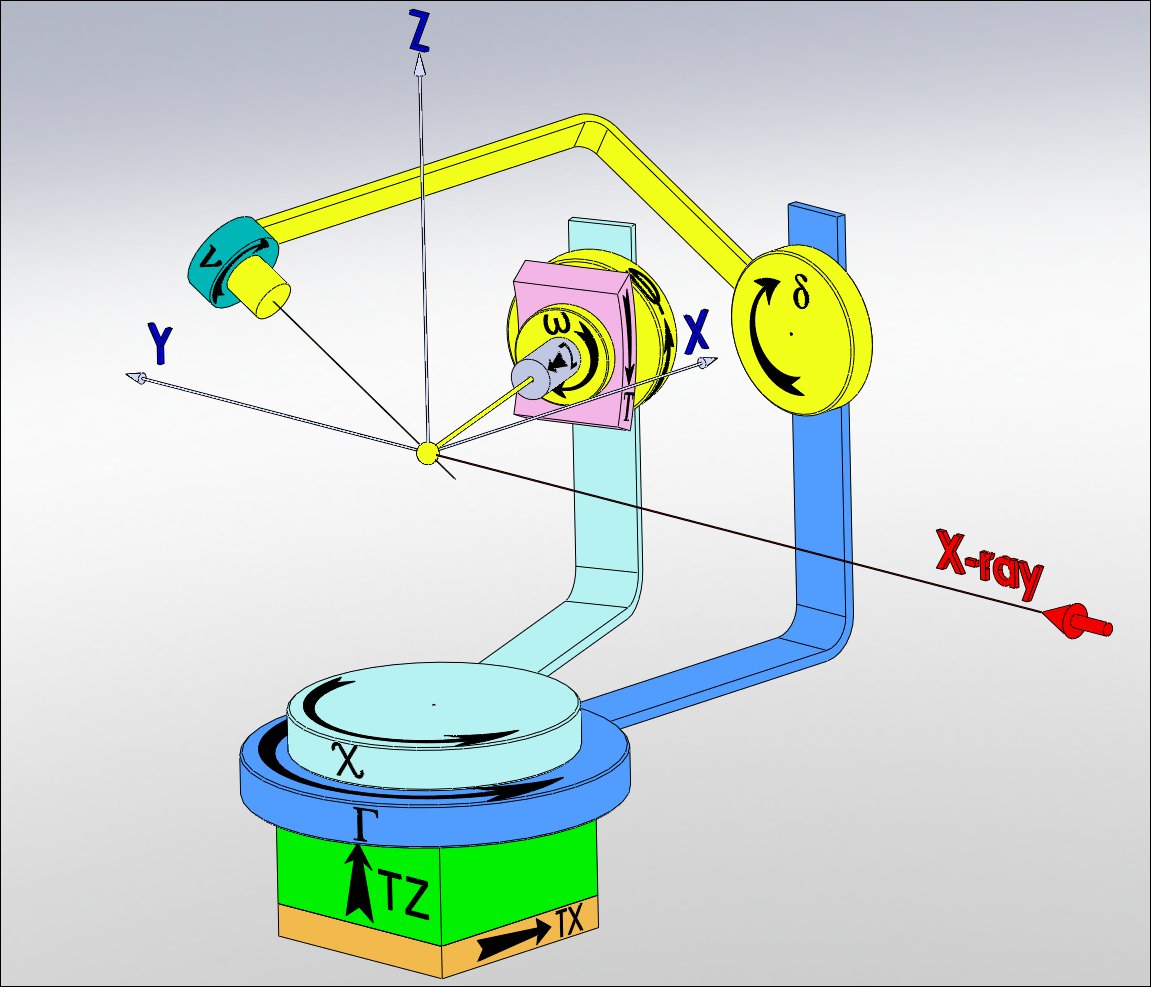

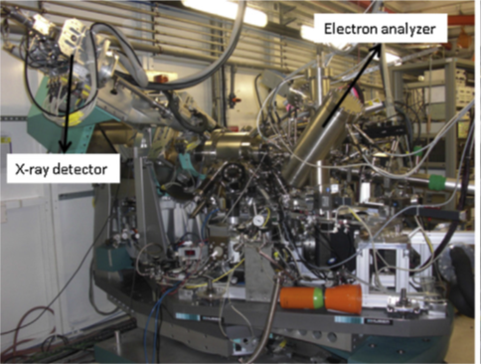

The experimental set-up includes a heavy 2S+3D diffractometer, a UHV chamber and an electrostatic analyser. The vacuum chamber has two Be windows so that the incoming and outgoing X-ray beam can hit the sample and the X-ray detector, respectively. The UHV system consists on a cylindrical vessel with 27 flanges, 19 of them pointing to the sample position. The sample surface is mounted vertically. The X-rays enter and leave the vacuum system through Be-windows, welded onto the stainless-steel chamber. The exit Be-window allows the out-going diffracted X-ray beam to cover 120º in-plane and 50º out-of-plane. The in-coming Be-window is wide enough to reach up to 50º X-ray incidence angle. A wide portion of the reciprocal space (Qmax=10 Å-1 at 12 keV) is therefore accessible. The UHV chamber has also MBE evaporation sources, an ion gun, an electron gun (up to 15 keV), an X-ray tube (Mg and Ti anodes), a UV discharge lamp, a LEED optics, a sample heating (up to 1800 K) and a cooling device (down to 20 K on the sample), leak valves, mass spectrometer and a load-lock for in-vacuum sample transfer. All these devices enable X-ray diffraction and UPS/XPS/HAXPES experiments during growth deposition or during different sample treatments. Figure XX shows a picture of the UHV experimental set-up. The analyser is an electrostatic cylinder-sector (FOCUS HV CSA), with a compact geometry and high transmission due to second order focusing. The analyser is based on a cylinder sector with 90° deflection and 300 mm slit-to-slit distance. The sample-lens distance is maximized to 50 mm, allowing the simultaneous accomplishment of photoemission and diffraction experiments. This gives a very compact design of the analyser that is easily integrated into a multipurpose experiment with different techniques. The analyser is capable of handling photoelectron kinetic energies from few eV up to 15 keV with the same analyser setup and power supply. The electron analyser is mounted on a 3- degrees=of-freedom motorized align basis so that the analyser focal point position can be swept on the sample. In this way, the detection geometry and consequently the counting rate can be optimized without changing the sample position or the in-coming beam impact point, i.e., without disturbing the diffraction geometry conditions. Recently, a 2x2 MAXIPIX (512x512 pixels) detector has been installed on the diffractometer detector arm reducing considerably the acquisition time for the diffraction pattern.

|

|

The sample moves on the diffractometer coupled into the vacuum by a rotating feedthrough. The feedthrough is composed of a differentially pumped rotating seal and a bellow that enables the adjustment of the vessel respect to the diffractometer. The diffractometer rotates the UHV chamber without moving the sample (requisite imposed by the GID experiment) so high and low kinetic energy photoelectrons could be measured in an optimal configuration. A specially designed mini-LEED mounted on a 63 mm flange is incorporated on the UHV system so that pre-characterisation of the ordered surface could be done. An ion bombardment gun, evaporation and gas leakage sources are also mounted on the UHV chamber that allows the possibility of doing X-ray diffraction and XPS experiments during growth deposition. Helium and nitrogen cooling system are incorporated so that low temperature experiments could also be performed.