- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2017

- Enabling technologies

- Real-time vacuum event analysis and localisation using FastVac

Real-time vacuum event analysis and localisation using FastVac

A new fast data acquisition system for pressure surveying has been implemented along the ESRF storage ring. High time resolution offers new perspectives for understanding vacuum events and deeper analysis such as their precise location around the ring.

Good vacuum and an associated control system for accelerator instruments are key parameters for performance, operational reliability and safety considerations. The ultra-high vacuum (UHV) conditions are required to minimise interactions of the electron beam with residual gas molecules.

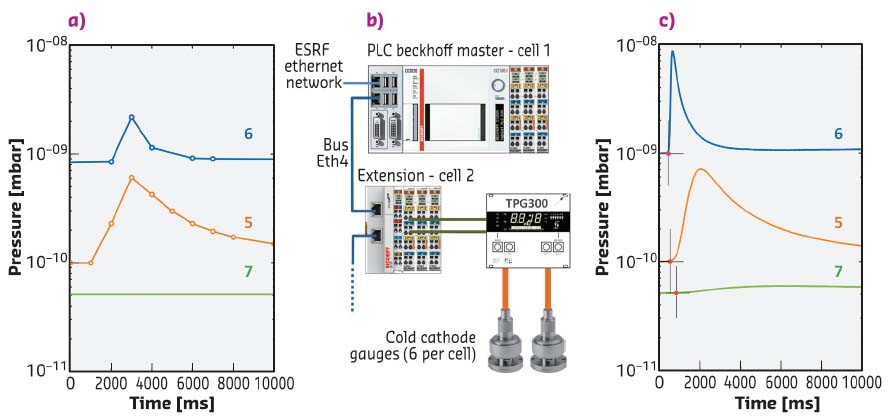

The ESRF storage ring consists of an 844 m-long assembly of vacuum chambers divided into 32 cells. Each cell is equipped with vacuum pumps (ion and getter pumps) and pressure gauges (cold cathode ionisation gauges). The gauge controller data is presently acquired through a serial interface (RS422) and archived in the hierarchical database (HDB) system at a maximum rate of one measurement per second. HDB-archived data for a typical event is illustrated in Figure 153a. The sampling rate is too low to allow for a detailed analysis of vacuum events lasting only a few seconds.

|

|

Fig. 153: a) Archived data for gauges 5, 6 and 7 of cell 11 with the standard acquisition system. b) Overview of the new hardware PLC FastVac system. c) Archived data with FastVac. |

FastVac is a new faster data acquisition and archiving system developed to collect the analogue output signals from gauge controllers. A programmable logic controller (PLC) was deployed along the technical gallery, as illustrated in Figure 153b. All signals resulting from the pressure gauges of the different cells are stored in a circular buffer within the PLC. The data are processed in real time to detect any sudden pressure changes and to trigger the archiving. The time resolution is increased by 100 compared to the standard system (Figure 153c), thus detailed analysis becomes possible.

Since the implementation, many events (some of which were not visible with the standard system) have been detected. Different types have been identified from quantitative and qualitative analysis. Events such as electron beam-induced outgassing when gauge responses are simultaneous, instrumentation issues and local pressure outgassing with evidence of pressure wave propagation can be observed.

A semi-empirical model has thus been developed with the goal of locating initial bursts of pressure within an UHV assembly. The model is based on the main assumption that the wavefront speed, Vf, is in the first order proportional to the conductance, C and a proportional constant, A (see formula below).

Vf(x,t) ∝ A(x0,t0) • C(x0,x) [1]

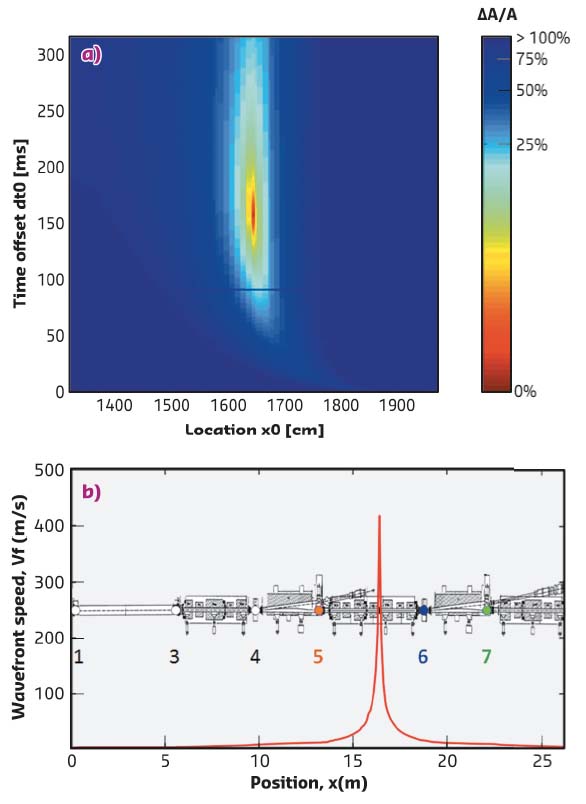

The conductance C depends on the vacuum assembly dimensions. MOLFLOW software [1] was used to calculate the conductance of vacuum chambers and each C(x0, x) calculated by discretisation using an average step ∆x = 10 cm. Fixing the range of physically possible (x0, t0) values corresponding to the event starting position and time, and applying the formula to each gauge signal, a solution exists if there is convergence of parameter A with a minimum of dispersion. Indeed, if A is a constant, its dispersion ∆A/A would be 0%.

This model was applied to analyse several different events recorded during User Service Mode (USM) runs and events generated in a test setup. Figure 154 illustrates computed results corresponding to the pressure event shown in Figure 153c. The x0 position has been determined with an estimated uncertainty of ± 15 cm and the ∆A/A dispersion parameter shows a strong convergence to a minimum of 1.3%. The pressure burst in that case corresponds to an outgassing resulting from the instability of RF fingers. The maximum wavefront propagation speed along the x axis is about 410 m/s and is in the order of magnitude of what is reported in literature for comparable studies [2-5].

|

|

Fig. 154: Schematic layout of cell 11 of the ESRF storage ring and FastVac data analysis results for a vacuum event localisation: a) dispersion (∆A/A) colour map for the (x0, t0) possible values and b) wavefront speed versus position along the cell. |

A combination of the FastVac system and a software application still under development will be very useful for real-time analysis of vacuum events during conditioning and operation of the new EBS storage ring.

Authors

A. Meunier and E. Burtin. ESRF

References

[1] R. Kersevan and J.-L. Pons, J. of Vac. Sci. & Tech A, 27, 1017 (2009).

[2] M. Ady, M. Hermann et al., IPAC2014, WEPME039, Dresden, Germany (2014).

[3] R.C. Dhuley and S.W. Van Sciver, Int. J. of Heat and Mass Transfer 96, 573-581 (2016).

[4] Y.-F. Song, C.-I. Chen et al., Rev. of Sci. Instruments, 57, 3063 (1986).

[5] T. Takiya, F. Higashino et al., J. of Vac. Sci. & Tech. A, 17, 2059 (1999).