- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2015

- Complex systems and biomedical sciences

- Interface alloy formation during the preparation of magnetic heterostructures capped with graphene

Interface alloy formation during the preparation of magnetic heterostructures capped with graphene

Graphene capped Co/Ir heterostructures have promising technological perspectives for the development of ultra-dense magnetic storage devices and of spintronic materials. Their preparation has been characterised with atomic resolution using surface X-ray diffraction techniques. Depending on the preparation procedure, a few atoms thick layer of a surface alloy can form and affect the final magnetic response of the system. This needs to be taken into account when tailoring the magnetic properties of such materials.

Graphene, the first easily accessible two-dimensional crystalline material, carries many promises for next generation technologies. Recently it has been shown that it is possible to induce a stable magnetic moment in the otherwise diamagnetic graphene by creating magnetic nanopatterns [1] or to manipulate the magnetisation of the ferromagnetic materials [2]. One relevant process to prepare magnetic graphene based heterostructures is intercalation, which consists of inserting species in between graphene and its support. This process is usually promoted by annealing a starting structure, e.g. a metallic layer deposited on top of the graphene sheet, at relatively high temperatures, typically a few hundred degrees centigrade.

Regarding the intercalation process itself, much effort has been focused on unveiling the intercalation pathways through a plain graphene sheet, but little attention has been given to the stability of the intercalated atomic layers. In particular, the interface between the ferromagnet intercalant and the metallic substrate has not yet been probed because the commonly used scanning probe microscopies and electron based spectroscopic techniques cannot directly and unambiguously characterise it. To overcome this problem, we have employed surface sensitive techniques based on synchrotron X-ray radiation at beamline ID03. These techniques are able to penetrate deeply into matter and provide structural/morphological information of buried interfaces. The structure of Co films obtained by deposition on a clean Ir(111) surface and on graphene-covered Ir(111), and subsequent annealing at 770 K, shows that the intercalation process facilitates the intermixing between Co and Ir and the formation of an interface alloy.

|

|

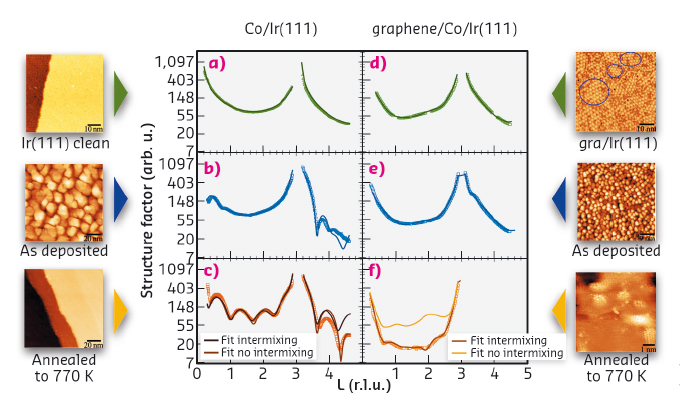

Fig. 77: X-ray reflectivity measured at RT (symbols) and fitted (solid lines) for: (a) bare Ir(111), (b) Co deposited on Ir(111) at RT, (c) the same sample annealed at 770 K, (d) graphene on Ir(111), (e) Co deposited at RT on graphene/Ir(111), (f) the same sample first annealed at 570 K and then further annealed at 770 K. Corresponding STM images are shown on the side. |

The qualitative evolution of the Co morphology was obtained by an observation of the X-ray reflectivity (XRR) profiles, presented in Figure 77. XRR measured before and after Co deposition on clean Ir(111) (Figure 77a, b) reveals that the Co/Ir interface has a very low roughness, similar to the one of the clean Ir(111) surface, while the vacuum/Co interface is rough. Annealing at 770 K for 5 min yields a Co thin film with a sharp Co/Ir interface and with a low surface roughness (Figure 77c).

The morphology of the thin Co film is different in the presence of graphene. Co deposition at room temperature yields a very inhomogeneous film (Figure 77d, e) and the graphene/Ir(111) substrate seems to be practically unmodified by the presence of the Co layer. Annealing at 570 K followed by 770 K results in a roughening of the Co/Ir interface (Figure 77f). STM images show that the surface of the system is much flatter than before and that graphene is again visible, confirming Co intercalation between the graphene layer and the Ir substrate.

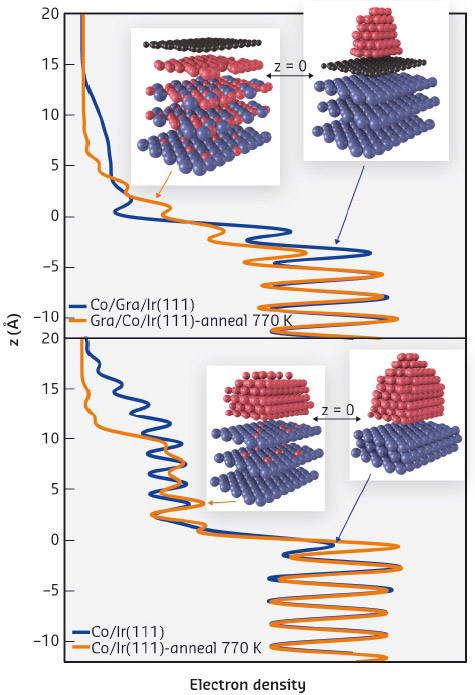

The XRR results are summarised schematically in Figure 78, where electron density profiles projected in the direction perpendicular to the surface are plotted together with the best fit models. The fits discriminate well between the sharp (non-intermixed) and rough (intermixed) interfaces.

|

|

Fig. 78: Electronic density profiles projected in the z direction perpendicular to the surface as deduced from fits of the XRR data, for Co deposited on Ir(111) at RT (bottom plot, blue line), the same sample annealed at 770 K (bottom plot, orange line), Co deposited on graphene/Ir(111) at RT (top plot, blue line), Co intercalated between graphene and Ir(111) at 770 K (top plot, orange line). |

In conclusion, we showed that an intermixing involving about 2 monolayers of the intercalant occurs during Co intercalation at 770 K. These results are valid only for the indicated temperatures and for defective graphene as different annealing temperatures will lead to a different intermixing. Our work suggests that annealing conditions must be chosen with care when targeting specific properties in graphene-based intercalated systems.

Principal publication and authors

Surface alloying upon Co intercalation between graphene and Ir(111), J. Drnec (a), S. Vlaic (b,c,d), I. Carlomagno (a,c,e), C.J. Gonzalez (b,c), H. Isern (a), F. Carlà (a), R. Fiala (f), N. Rougemaille (b,c), J. Coraux (b,c) and R. Felici (a), Carbon 94, 554-559 (2015); doi:10.1016/j.carbon.2015.07.039.

(a) ESRF

(b) CNRS, Inst NEEL, Grenoble (France)

(c) Univ. Grenoble Alpes, Inst NEEL, Grenoble (France)

(d) LPEM-UMR8213/CNRS-ESPCI ParisTech-UPMC, Paris (France)

(e) Università degli Studi Roma Tre (Italy)

(f) Charles University, Prague (Czech Republic)

References

[1] R. Decker et al., Phys. Rev. B 87, 041403 (2013).

[2] N. Rougemaille et al., Appl. Phys. Lett. 101, 142403 (2012).