- Home

- News

- Spotlight on Science

- Degradation of silicon-based...

Degradation of silicon-based anodes for lithium-ion batteries followed by in situ X-ray tomography

21-05-2019

The cracking and interface debonding dynamics of Si-based electrodes for Li-ion batteries have been studied by in situ synchrotron X-ray tomography. This study reveals the positive impact of a “maturation” procedure on the mechanical properties of the electrodes resulting in a better cyclability.

Si-based anodes have potential to replace favourably the usual graphite electrodes to increase the energy density of lithium-ion batteries. However, Si-based electrodes suffer from high volume change during lithiation/delithiation cycling, which degrades their structure and shortens the lifetime of the batteries. The degradation includes electrode cracking and delamination, Si particle fracturing and instability of the solid electrolyte interphase (SEI) [1]. Significant research efforts are being made to control such expansion effects and improve the cyclability. Since battery anodes have complex and heterogeneous structures, 3D observation is required to better understand their failure mechanisms and thus subsequently optimise their formulation [2]. Therefore, it is pertinent to monitor the morphological changes of the electrode occurring during its operation and at different scales.

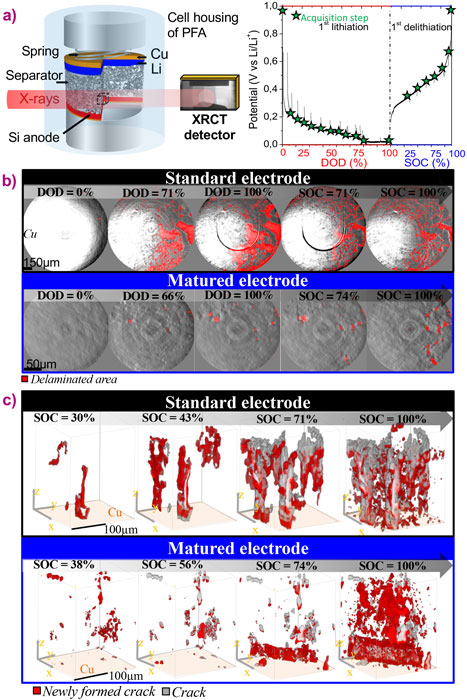

The 3D microstructure evolution of two different anodes was studied in situ during one discharge/charge cycle by means of X-ray tomography (Figure 1a). The standard electrode obtained by routine preparation was scanned at Psiché beamline at Synchrotron Soleil whereas the electrode prepared with a “maturation” step [3], which consists of storage of the electrode for a few days under a humid atmosphere prior to drying and cell assembly, was imaged at beamline ID16B at the ESRF resulting in an analysed volume of 256 × 256 × 210 μm3 with an isotropic voxel size of 200 nm.

Subsequently, the dynamics of the expansion and contraction, of the electrode cracking in the bulk (cracks are shown in red in Figure 1b) and of the debonding at the interface with the current collector (Figure 1c) of these two different electrodes were visualised in 3D and compared quantitatively for volumes of 190×190×210 μm3 with high resolution.

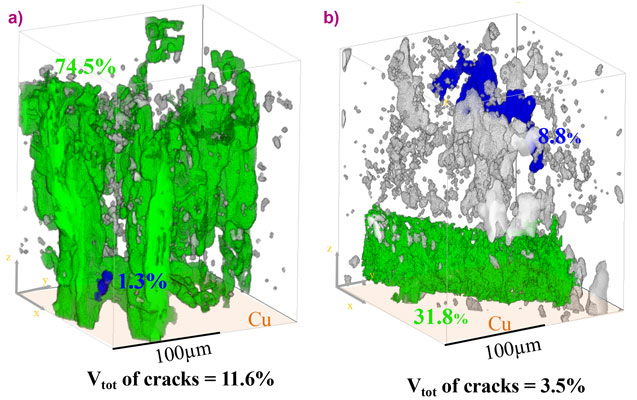

From these analyses, it was shown that the “maturation” treatment limits the macroscopic deformation (expansion/contraction) of the electrode by constraining the displacement of the Si particles. Its most important effect was to decrease the formation of macro-cracks in the composite electrode by a factor of four (Figure 2) and reduces its delamination from the current collector by a factor of ten. The intra-connectivity and propagation directions of the cracking pattern was analysed for both electrodes (Figure 2). This reveals that a simple “maturation” procedure can significantly enhance the mechanical properties of the binding phase in the composite electrode. Thereby, the active material network can better adapt to the important volume variations induced by the silicon alloying with lithium through a more ductile and resilient electrode, resulting in a major gain in its cyclability [3].

A time resolved video, corresponding to Figure 1c, of the crack volume evolution of both electrodes upon their delithiation can be visualised by following this link: youtu.be/mLh74E81Yfc.

Principal publication and authors

Dynamics of the morphological degradation of Si-based anodes for Li-ion batteries characterized by in-situ synchrotron X-ray tomography, V. Vanpeene (a,b), J. Villanova (c), A. King (d), B. Lestriez (e), E. Maire (b), L. Roué (a), Adv. Energy Mater. 9, 1803947 (2019); doi: 10.1002/aenm.201803947.

(a) Institut National de la Recherche Scientifique (INRS), Centre Énergie, Matériaux, Télécommunications (EMT), Varennes (Canada)

(b) INSA Lyon, MATEIS, CNRS UMR 5510, Villeurbanne (France)

(c) ESRF

(d) Synchrotron Soleil, Gif‐sur‐Yvette (France)

(e) Institut des Matériaux Jean Rouxel (IMN), CNRS UMR 6502, Université de Nantes (France)

References

[1] M.N. Obrovac, Current Opinion Electrochem. 9, 8–17 (2018).

[2] P. Pietsch, V. Wood, Annu. Rev. Mater. Res. 47, 451–479 (2017).

[3]C. Reale Hernandez, A. Etiemble, D. Mazouzi, Z. Karkar, E. Maire, D. Guyomard, B. Lestriez, L. Roué, Adv. Energy Mater. 8, 1701787 (2017).