- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2013

- Status of the Upgrade Programme

Status of the Upgrade Programme

Status of the Upgrade Programme

After two years of work on our ambitious construction programme, 2013 has seen the delivery of the new buildings that change not only the visual appearance of the site but more importantly create new opportunities for the science programme at the ESRF. Immediately after the delivery of the new buildings (ID16 satellite, Chartreuse and Belledonne halls), work on new beamlines commenced with many beamlines now under construction. 2014 will see the inauguration of many new beamlines with unprecedented scientific capabilities offered to our user community. The upgrade of the accelerator complex is heading towards a successful conclusion with the first encouraging tests on top-up operation during machine dedicated time. We are now eagerly awaiting the full implementation of top-up operation in 2015 for the timing modes. We thank our staff for all of these achievements, delivered while the facility was kept in full user operation.

EX2 – Signing off

Eight years after the inception of the ambitious EX2 construction project, we are now ready to sign off. The last phase, which consists in finalising the accounts of the project, is going ahead and will hopefully be concluded early 2014.

The climax of the first half of 2013 was the completion of one of the major technical challenges: the high quality slab. The technical design choice was the fruit of a thorough analysis and scrutiny by an international panel of experts to meet stringent requirements in terms of stability and vibration, critical for the construction of highly demanding nanofocussing beamlines. The last layer of the multilayered slab, consisting of densely steel-reinforced concrete, was poured in two distinct operations during the month of April. For the Belledonne hall, 800 m3 of concrete had to be brought in and was poured in one go, whereas the smaller Chartreuse hall required “only” 525 m3.

On 24 June an official ribbon cutting ceremony was held to commemorate the inauguration of the halls (Figure 1), attended by Council delegates and observers, ESRF Directors, and key contributors in the realisation of EX2.

|

|

Fig. 1: Inauguration ceremony of the new experimental halls, 24 June 2013. |

Beamline construction started immediately after the delivery of the new halls with ID30 in Chartreuse and ID32 in Belledonne.

The occupation of the new premises began in the fourth quarter of 2013 with the delivery of the last part of the building programme, the Laboratory and Office Building in front of the Belledone hall extension (Figure 2).

|

|

Fig. 2: The finished Laboratory and Office Building in front of the Belledonne hall extension. |

Logistics require the careful orchestration of moves affecting a large fraction of the ESRF staff over the next 12 months.

The penultimate phase of the project is settling the accounts with the contractors. At the time of writing, this chapter of the project is still under way and we are confident that the project will be concluded within budget.

Upgrade of the source

The upgrade of the accelerator system is progressing well and as planned. The extension of the ID23 straight section to 7 metres has been completed. This change in magnet configuration had the consequence of breaking the symmetry of the lattice but these significant changes to the optics had no negative effects on machine performance. In fact, beam parameters are even better than previously thanks to improved tuning techniques.

The 7-metre section enabled tests of low-b optics, which were carried out with success, paving the way for the possible development and installation of shorter-period, smaller-gap undulators. Upon completion of these tests, three new HOM-damped RF cavities were installed and are currently operating in active mode, powered by the new SSA amplifiers.

The storage ring top-up operation project is advancing well. The hardware related activities necessary to complete the project are under development. Very encouraging tests have been carried out, so far mostly in machine dedicated time. Further tests with users will be scheduled in 2014 in order to prepare the final top-up delivery during user operation in 2015.

The technical design study for the Phase II upgrade based on a 7-bend achromat lattice is progressing well. The project was received with enthusiasm by the Accelerator Project Advisory Committee (APAC) in September, who then produced a very positive official report.

Renewal of beamlines

Activities within the Instrumentation and Development Division (ISDD) and the Experiments Division (ExpD) for the construction of new upgrade beamlines (UPBLs) have reached their peak with the delivery of the experimental hall extensions. A total of 10 beamlines is currently under construction with most of them to return to user operation in 2014. In addition, significant financial and human resources have been invested in the continuous refurbishment and further development of the remaining beamlines.

The main projects for beamline renewal are as follows:

UPBL1 – Diffraction for nano-analysis

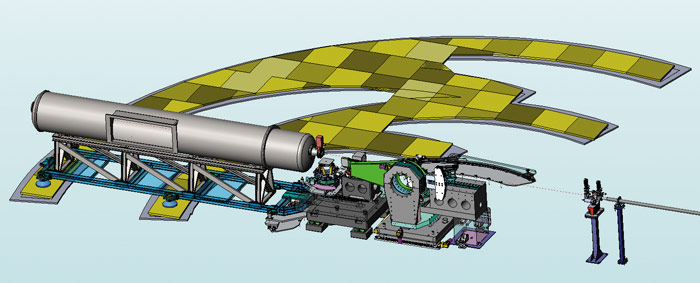

Most of the optical components, including the white beam mirrors and multilayer monochromator, double crystal monochromator and transfocator are currently in the manufacturing or procurement phase. The SAXS/GISAXS end-station is in the final phase of design (Figure 3).

The prototype for the ultra-long-working-distance microscope has been finalised.

|

|

Fig. 3: CAD picture of UPBL1 SAXS and GISAXS end station. |

UPBL2 – High energies for interfaces and materials processing

The design of the multilayer device (based on ESRF generic mechanical systems for mirrors) is near to completion. The outline of the beamline layout is finalised and the contracts for the construction of the infrastructure have been signed. The procurement of multilayer monochromator substrates has been initiated, and the evaluation of commercial flat panel detectors completed.

UPBL4 – Nano-imaging and nano-analysis

Overall the project is progressing well. The optics hutch was completed in June 2013 and all optics hutch components have now been installed, with first commissioning results proving satisfactory. There is still a significant effort to be devoted to control software.

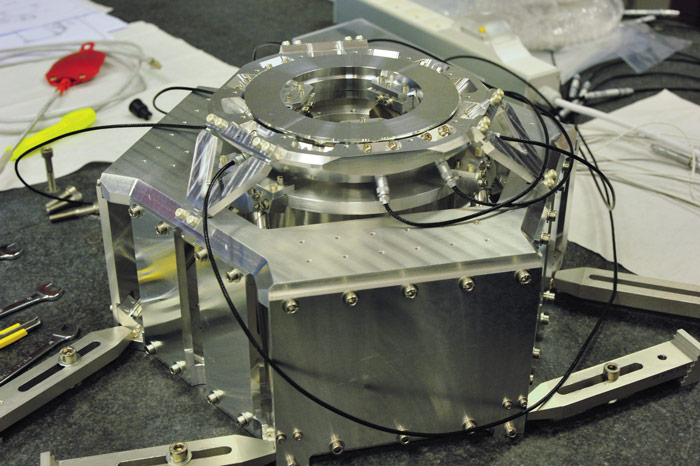

NI- nanotomography endstation: The pre-focusing multilayer monochromator is now installed and the medium energy (17 keV) nanofocusing mirror substrate is in the manufacturing phase. The piezo hexapod is operating correctly, thus making it possible to compensate the errors of the sample rotation. The production of the main components for a composite device combining customised Maxipix modules and two 16 Mpixel imaging detectors, including a FReLoN camera, with specially designed lenses has been completed and the instrument is in the assembly phase. Figure 4 shows the nanotomography sample stage.

NA- nano-analysis endstation: The white-beam double mirror system has been installed. A Ge solid-state detector for high energy fluorescence measurements and two multi-element SDD detectors have been purchased.

|

|

Fig. 4: UPBL4 NI nanotomography end station sample stage. |

UPBL6 – Hard X-ray spectroscopy (RIXS & XRS)

The assembly of both spectrometers has been completed and successful commissioning results have been obtained. Maxipix and APD detectors have been delivered and two on-line diamond BPMs were installed. Target energy resolution has been slightly surpassed and first scheduled user experiments on the RIXS and NIXS spectrometer have been successful.

UPBL7 – Soft X-ray spectroscopy (RIXS & XMCD)

All mirror mechanical devices have been assembled, and are now awaiting the integration of the mirror substrates. Entrance and exit slits have been delivered and tested. Spherical grating substrates were delivered to the ESRF for intermediate metrology tests prior to the final manufacturing phase. The plane grating monochromator has been delivered and the liquid nitrogen cooled grating pre-mirror assembly will be integrated soon. Finally, the installation of the 11 m long RIXS spectrometer arm is under way.

UPBL9a – Time-resolved ultra-small-angle scattering

The mechanical assembly of the double mirror device has been completed, and is now waiting for mirror substrates. The 32 m long SAXS tube and associated equipment are in the manufacturing phase and will be delivered early 2014. The SAXS and WAXS detectors have been purchased, while a specially designed new high-sensitivity FReLoN detector for USAXS applications has been manufactured.

UPBL9b – Pump-probe and time-resolved experiments

The TDR has been validated and a new high heat-load beam chopper has been ordered.

UPBL10 – Automated crystallographic evaluation

Following the installation and commissioning of all major optical devices, the beam has been delivered to the three end-stations. An order has been placed for the new Pilatus 6M detector. The MxCube V2 control software, which was successfully used to take the first data at the end of September 2013, is now complete. It was decided to delay the start of user operation on ID30A-1 and ID30A-3 to prepare the installation of the new high capacity dewar and the new robot system for fast sample transfer and goniometry.

UPBL11 – Time-resolved and extreme conditions XAS

A first series of on-site acceptance tests of the XH Ge microstrip detector for time-resolved EDXAS have been carried out and the Lima drivers were developed by the STFC with the help of the ESRF. The acquisition sequences were prepared with the XH simulator from the STFC. This allowed the XH detector to be integrated into the beamline before it arrived.

ID22 refurbishment

The TDR for the move and complete refurbishment of the powder diffraction beamline from ID31 to ID22 has been completed and validated. The infrastructure for the new beamline has been prepared and installation of the new components in the optics and experimental hutches is progressing well.

Other activities in the ISDD have continued to focus on UPBLs and related beamline instrumentation, although reflection has begun on the instrumentation programme for Phase II and, more particularly, on future detector developments.

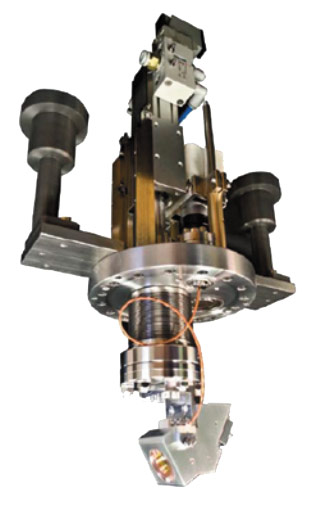

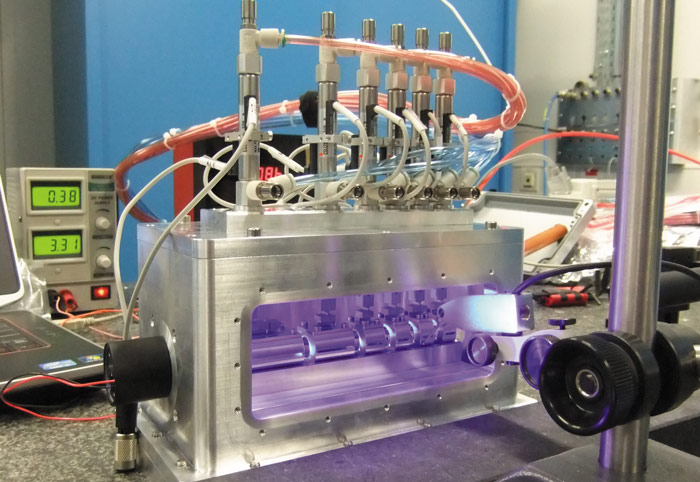

Several developments were driven by the very challenging specifications of optical components for UPBLs. A special effort has been made to enhance optical metrology capabilities, including protocols for measurement of sub-nm figure errors on short radius and highly aspheric reflective optics, precise measurement techniques for variable line spacing diffraction grating characterisation and improved instrumentation for stitching interferometry methods. As in previous years, special efforts were put into establishing generic engineering solutions to minimise the resource investment required for their integration into customised systems. A large number of standard XBPMs and beam viewers were produced and installed on about 15 different beamlines (Figure 5). A new, very compact transfocator has also been developed and commissioned for integration into the limited space typically available around sample environments (Figure 6).

|

|

Fig. 5: Monochromatic beam viewer in sample stage. |

|

|

Fig. 6: Compact transfocator undergoing tests. |

Moving into the later phases of the remaining UPBLs, the Detector & Electronics Group has dedicated significant resources to the selection, installation and integration of high performance detector instrumentation. This has been facilitated by earlier efforts to identify standard solutions based on commercial devices, which can be tailored to specific beamline needs. R&D activities include definition of the readout architecture and successful testing of Medipix3 chips at the 350 MHz clock frequency for the SMARTPIX project; the development of new high efficiency semitransparent scintillating screens; progressing in the construction of the first full 1 kpixel XNAP detector prototype based on pixelated APD sensors; and continuation of the HiZPAD2 project (CALIPSO Joint Research Activity) for high energy pixel detectors.

The modernisation of the control system is on-going, following two directions: on one hand the generalisation of the standard motion controller, IcePAP, on both beamlines and the accelerator, is being pursued. On the other hand, the first elements of the R&D programme for new control software have been put in place.

Finally, in 2013, the strengthening of commercial & outreach activities took place for several European partnerships, and included the supply of a number of optical components and detectors to other facilities, collaborations with E-XFEL for the design of one endstation at DESY, and the Solar Innovation collaboration with the CEA.

B. Dijkstra, R. Dimper, H. Reichert, P. Raimondi and J. Susini