- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2011

- Enabling technologies

- New focusing record with dynamically-figured multilayer mirrors

New focusing record with dynamically-figured multilayer mirrors

The ID22NI (nanoimaging) endstation has recently benefitted from a significant improvement in its focused beam characteristics thanks to a new focusing multilayer mirror system wholly designed and assembled at the ESRF. Users are now able to routinely access beam sizes of 59 x 43 nm2 (H x V) with photon flux of 1012 ph/s corresponding to a record flux density of 1.5 x 108 ph/s/nm2.

For micro or nanoprobe X-ray applications, the Kirpatrick-Baez (KB) configuration consisting of two successive mirror reflections in perpendicular planes is commonly used to produce a finely focused beam at the experimental station. In this scheme, one mirror focuses the beam vertically and a second mirror horizontally. As part of a long-running ESRF development programme, optomechanical systems have been implemented that create the required elliptical cylinder figures through precise bending of initially flat mirror substrates [1]. The bending is controlled using motorised actuators and can be readily adapted to the experimental requirements, allowing flexibility in the choice of the mirror focal length and incidence angle. Systems based on these in-house technologies are installed at around half of the ESRF beamlines. Due to high mirror reflectivities, large acceptances and achromatic focusing behaviour, this approach is capable of delivering exceptionally high fluxes into small focus probes.

Often the KB systems are used in combination with multilayer coated substrates. This allows the mirrors to be used at larger incidence angles and is particularly beneficial for use at high energies and/or to increase the acceptance for a given mirror length. Multilayers reflect a restricted energy band pass (typically ~1-10%) at an energy governed by the Bragg diffraction law. Consequently, if the beamline application demands energy tunability then the incidence angle must be adjusted according to the required energy. In this instance the dynamical figuring becomes particularly powerful since it allows the mirror figure to be optimised at different X-ray incidence angles.

For ID22NI, these mirror bending technologies have been pushed to their limits in providing a KB system which can routinely deliver high-flux hard X-ray beams focused in two dimensions to the 50 nm scale at a standard length ESRF beamline.

The system consists of two W/B4C multilayer coated mirror substrates adhesively bonded to flexure-hinge based bender systems and assembled in the KB configuration. The high demagnification ratios and short working distances needed to guarantee the small beam size require the mirrors to be bent to radii as short as 14 m. To achieve the required slope errors it was necessary to optimise the width profile of the mirror substrates using an iterative finite element analysis procedure. The mirrors were manufactured from silicon with control of the substrate width with a precision better than 2 µm then polished using classical techniques. Due to the curvature of the bent substrates, the incidence angle of the X-rays varies strongly along the mirror and necessitates a variation in the multilayer d-spacing to ensure that the required photon energies are efficiently diffracted along the full mirror length. The deposition of high quality multilayers with such steep d-spacing gradients is challenging but these were successfully manufactured at the ESRF Multilayer Laboratory.

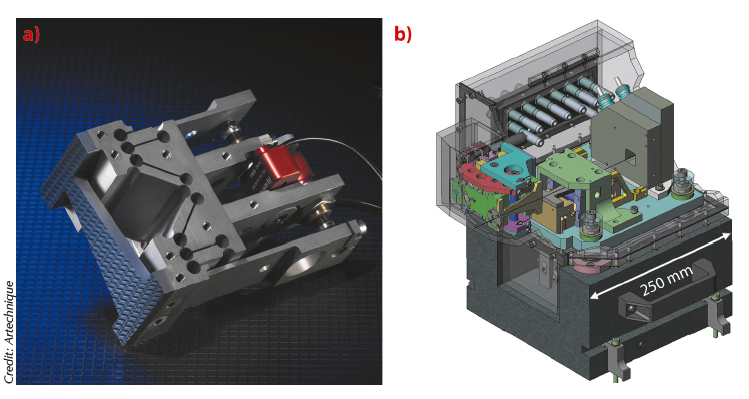

The coated mirrors were bonded to their respective bender mechanisms (Figure 152a) and the quality of the bent figure verified at the ESRF Optical Metrology Laboratory. The measured slope errors were as low as 0.06 (0.11) µrad RMS for the vertically (horizontally) focusing mirrors. Following integration in a highly compact KB assembly designed to minimise thermal drifts and vibrational instabilities (Figure 152b), the system was installed at the ID22NI end-station.

|

|

Fig. 152: a) The horizontally focusing mirror bender design. b) a schematic of the ID22NI KB system. |

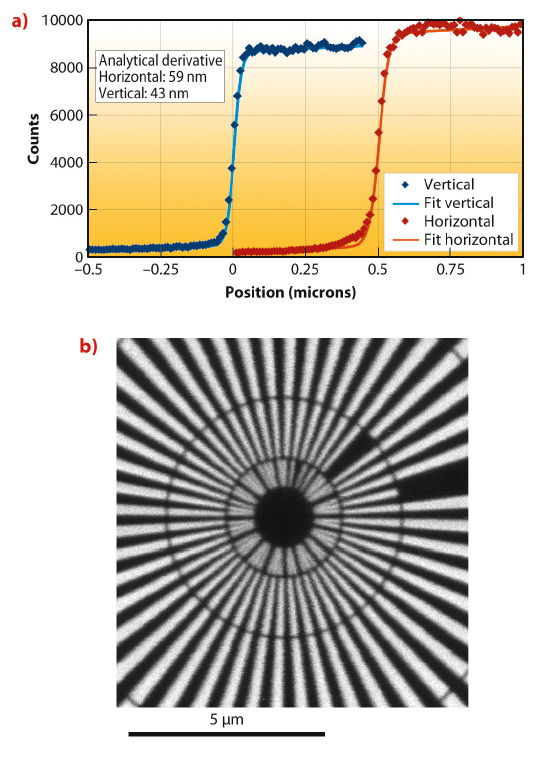

At ID22NI the system operates at photon energies in the range 17-30 keV with ‘pink’ beam illumination with the multilayer energy band pass (~8%) relaying the emission of the single line undulator source (energy band width ~1.7%) with a transmission in excess of 50%. Figure 153a shows measurements of the beam profile performed at 17 keV demonstrating a focal spot size of 59 x 43 nm2 FWHM (HxV). Figure 153b shows an X-ray fluorescence map of a test sample acquired using the focused beam - other examples of measurements made using the system appear elsewhere in these highlights.

These new developments are the fruit of a close collaboration between the X-ray Optics, Advanced Analysis & Modelling and Mechanical Engineering Groups of the ISDD and the ID22 beamline team. In addition, software developments by the ISDD Beamline Control Unit have made focusing optimisation within the beamline environment rapid and reliable.

Principal publication and authors

R. Barrett, R. Baker, P. Cloetens, Y. Dabin, C. Morawe, H. Suhonen, R. Tucoulou, A. Vivo, and L. Zhang, Proc. SPIE 8139, 813904 (2011).

ESRF

References

[1] Zhang et al., J Synchrotron Rad 5, 804-807 (1998).