- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2006

- Surface and Interface Science

Surface and Interface Science

Introduction

The year 2006 has been both eventful and productive for surface and interface science (SIS) at the ESRF. Beamline ID03 came back on line after roughly one year of rigorous refurbishment and rebuilding. For twelve years ID03 has been a benchmark beamline for surface X-ray diffraction (SXR). To continue serving the European surface X-ray diffraction community with the same level of excellence, an upgrade of the beamline was necessary. Now, two large hutches are available for experimental equipment. The first (EH1) houses a vertical axis 2 + 2 diffractometer, dedicated to surface characterisation during heterogeneous catalytic reactions. A batch reactor with a gas handling system is also available to users. The second hutch (EH2) houses a horizontal axis diffractometer coupled with a (refurbished) UHV chamber for in situ surface preparation and growth. There is also a surface magneto-optic Kerr effect setup for the characterisation of magnetic thin films.

The beamline is windowless up to the experiment and served by three 11 mm gap undulators. The first optical element is a highly stable, cryogenically cooled, monolithic Si(111) double-crystal monochromator, optimised for 5 to 24 keV. Horizontal focussing is performed by a cylindrical mirror with variable bending radius. A second flat mirror keeps the beam horizontal. Both mirrors in the first optics hutch are palladium coated, delivering a flux exceeding 1013 ph/sec (at 200 mA) to a spot size of 45 x 35 µm2 (H x V), which corresponds to a three-fold increase of the flux at the sample in both experimental stations. A short focal length Kirkpatrick-Baez (KB) focussing system allows spot sizes in the µm range on the samples.

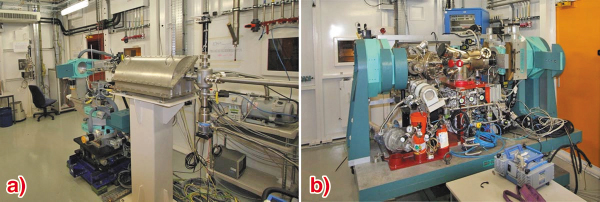

The “resurfaced” ID03 beamline (Figure 79) is now not only suited to surface crystallography but also allows in situ GISAXS studies, coherent surface diffraction, and anomalous scattering experiments owing to the non-dispersive focussing elements, thus providing new opportunities in surface science. Increased flux as well as increased speed of the diffractometers and data acquisition should allow users to study time-dependent phenomena, e.g. during heterogeneous catalysis under real conditions.

Fig. 79: The refurbished ID03 beamline: a) Vertical axis diffractometer in EH1 to accommodate small sample environments. The KB system in the foreground focuses down to the micrometre range. b) Horizontal axis diffractometer with UHV chamber for in situ preparation and growth in EH2.

The other beamlines of the SIS group, ID01 and ID32 have not been idle either. The beamline review panel acknowledged the success and productivity of ID01. This beamline is now continuing its path under full steam towards new applications using microfocussing and coherent scattering. The staff of ID32 has commissioned a new primary monochromator, which improves flux, versatility, reliability, and beam quality for the two stations (SXRD and XSW/XPS) at the beamline.

The three insertion device beamlines ID01, ID03, and ID32 of the SIS group, with about 50% (ID01) and 90% (ID02 and ID32) of their beamtime scheduled for SIS experiments represent the SIS specialists together with the French CRG beamline BM32 (70% SIS). However, more than 80 SIS proposals are typically received each proposal round and roughly 50% of all beamlines end up on the list of the SIS beamtime allocation panel. Thus, besides reports originating from the usual culprits, these SIS highlights also feature contributions from the French-CRG beamline BM02 (typically 40% SIS) and the UK-CRG beamline BM28 (typically 20% SIS).

Continuing the trend of the last years, the SIS highlights are dominated by non-classical SIS. While experimental work in the area of classical SIS such as surface crystallography is certainly continuing, is has become routine and the study of some new surface structure is no longer guaranteed to create much excitation, unless there is some interesting twist. “Runts”, no wimpy dwarfs, but nicely “rolled-up-nano-tubes”, are in fact twisted enough. In the first contribution, the detailed analysis of these nifty structures at ID01 is reported. This is followed by another ID01 experiment: the diffraction analysis of nanodot pattern produced by ion sputtering. The third contribution is also about nanoscience and in this case the analysis of the influence of capping layers on the structure of quantum GaN dots was investigated by anomalous diffraction at BM02.

The next section contains two contributions about the investigation of thin films: Pr2O3 on Si(001) was grown in the surface characterisation laboratory of ID32. Pr2O3 is a possible candidate to replace SiO2 in the CMOS devices and the structure of the Si(001)/Pr2O3 interface has been scrutinised at ID32 using a wide range of surface science techniques. Shallow implanted As layers in Si, likewise important for future devices, were investigated at ID01 by diffuse scattering, and a report is given in the second contribution.

Three contributions belong to the field of surface chemistry: The in situ X-ray analysis of the homoepitaxial growth of gold from electrolyte was performed at ID32. The structure and reactivity of a PtRh alloy catalyst under real catalytic conditions was investigated at ID03. The surface chemical aspects of cultural heritage artefacts were investigated at BM28 with the aim of finding ways of protecting such priceless items from decay.

Finally, the last contribution reports about a seemingly impossible investigation of the magnetic semiconductor GaMnAs, i.e., identifying the detailed lattice site distribution of Mn at very low concentration of 4% in a just 4 nm thick GaAs film. The XSW imaging technique allows one to “see” the majority of Mn on Ga substitutional sites and data refinement gives the exact quantity (< 10%, depending on post-growth treatments) of Mn on the (magnetically inactive) As interstitial site.

We think that these contributions provide an impressive account of the range of investigations in surface and interface science today and we hope that you will enjoy the reading.

J. Zegenhagen