- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2010

- Structure of materials

- Determining grain-resolved stresses in polycrystalline materials using three-dimensional X-ray diffraction

Determining grain-resolved stresses in polycrystalline materials using three-dimensional X-ray diffraction

A new technique permitting characterisation of the position, orientation, size, and also the average stress state of each grain embedded in the bulk of a polycrystalline material during in situ processes would be a powerful tool for the materials scientist.

|

|

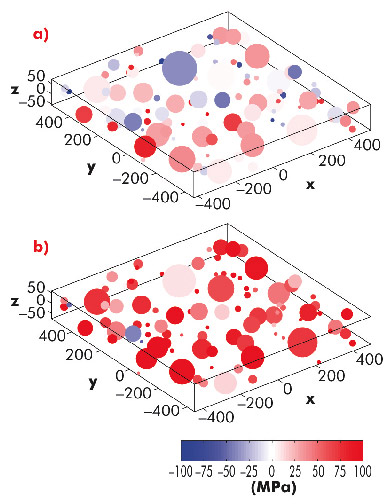

Fig. 28: Centre-of-mass grain positions within the mapped layer at a) 5 MPa and b) 60 MPa. The unit on the axes is micrometres and the tensile axis is along z. The relative grain volumes are indicated by the size of the spheres. The grains are colour coded according to the axial stress tensor component (see colour bar). |

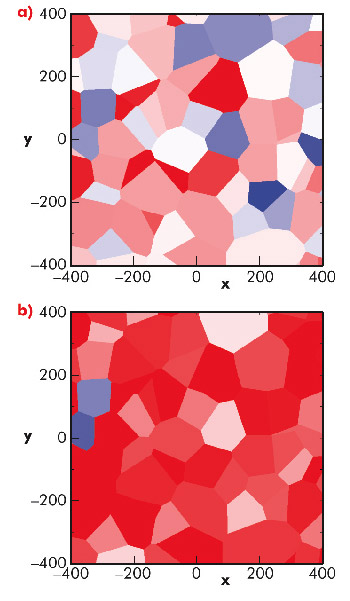

Here we present the first results obtained by extending the three-dimensional X-ray diffraction (3DXRD) microscopy technique implemented at beamline ID11 to include the characterisation of grain-resolved stresses in around 100 grains. The material under investigation was a tensile sample of interstitial-free steel with a grain size of 0.1 mm and a cross section of 1 x 1 mm2 mounted in a stress rig. The beam was defined with slits to illuminate a layer of thickness 0.15 mm covering the entire cross section of the sample perpendicular to the tensile axis. For each illuminated grain in the ensemble, a robust 12-parameter-per-grain fit of the centre-of-mass position, orientation and stress tensor, including error estimation and outlier rejection was performed using a newly developed algorithm. The precision obtained for each grain was approximately 10 µm in position, 0.05° in orientation, and 30, 50 and 15 MPa in the axial, normal and shear components of the stress, though some grains may have larger errors. The relative volumes of the grains were calculated from the peak intensities. A total of 96 grains were monitored during elastic loading and unloading. The centre-of-mass positions, relative volumes and axial stresses of the grains at 5 MPa and 60 MPa are given in Figure 28. From the results, a three-dimensional orientation and stress/strain map of the polycrystal can be obtained by e.g. Laguerre tessellation [1] as shown in Figure 29. This can be used to determine the neighbour relations of the individual grains.

|

|

Fig. 29: Laguerre tessellations corresponding to the data shown in Figure 28 showing the neighbour relations of the grains. |

It should be emphasised that the data acquisition is fast enough to enable mapping of a representative volume within the sample, and that studies of up to 1000 grains have been performed [2]. Furthermore 3DXRD is easily combined with simultaneous tomography, relevant for applications such as visualising the location of reinforcements in composite materials or following the evolution of cracks.

In conclusion, a method has been developed that enables the study of metals and alloys which are typically polycrystalline and processed by plastic deformation and annealing. It is the stress evolution in processes like these, as well as in phase transformations, that can now be determined in situ at the single-grain level. The results can be correlated with grain sizes, orientations and neighbour relations and exploited in disciplines such as materials design and polycrystal deformation theory. In the latter, the ability to pinpoint active slip systems and study the effects of grain interactions is crucial for validating and extending the present polycrystal deformation models. This can be done with greater confidence from the present data. Finally the technique can be used to study local phenomena such as the stress field around a crack tip. If the material is too coarse grained for traditional strain scanning methods to apply, each grain may be used as an independent probe and a much improved map in terms of spatial resolution can be obtained.

Principal publication and authors

J. Oddershede (a), S. Schmidt (a), H.F. Poulsen (a), H.O. Sørensen (a), J. Wright (b) and W. Reimers (c), J. Appl. Cryst., 43, 539–549 (2010).

(a) Center for Fundamental Research: Metal Structures in Four Dimensions, Risø DTU, Roskilde (Denmark)

(b) ESRF

(c) Technische Universität of Berlin, Berlin (Germany)

References

[1] A. Lyckegaard, E.M. Lauridsen, W. Ludwig, R.W. Fonda and H.F. Poulsen, Adv. Eng. Mater., in press, 2010; DOI: 10.1002/adem.201000258.

[2] J. Oddershede, S. Schmidt, H.F. Poulsen and W. Reimers, Mater. Sci. Forum 652, 63-69 (2010).