- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2008

- Materials science

- Crystallisation and dissolution of flow-induced precursors

Crystallisation and dissolution of flow-induced precursors

Easy processability of polymeric materials is a parameter that is of crucial importance to promote their use in an increasing number of both high-tech as well as commodity applications. Production of polymeric materials often involves shaping the product from the melt by applying flow at high temperatures (thermo-mechanical history). The flow rate and temperature can strongly influence the final properties of the material. For semi-crystalline polymers, the link between this thermo-mechanical history and the properties is reflected in the crystalline structure and morphology.

The crystallisation of these entangled, i.e. spaghetti like, macromolecules poses intriguing problems from a fundamental scientific viewpoint but obviously has implications for applied material technology as well.

|

|

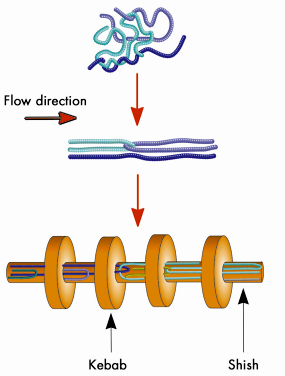

Fig. 27: Schematic representation of coiled macromolecules that can be stretched with flow and crystallise into highly-anisotropic shish-kebabs. |

It is well established that when a strong flow is applied to a polymer melt, the molecules orient and stretch with the flow. When the temperature is sufficiently low, orientation and stretch of the molecules can be frozen-in with the onset of crystallisation (Figure 27). Anisotropic (fibrillar) crystals are formed and, in the next stage, overgrown by disk-like lamellae. This crystalline morphology is called shish-kebab because of the analogy with the Mediterranean meat dish. The origin of this morphology is currently a topic of discussion. It is well accepted that the initial stages of the process are very important and synchrotron scattering techniques, based on SAXS and WAXD, have proven indispensible for these studies. Experiments from our group at the Technische Universiteit Eindhoven, performed at the Dutch Belgian beamline BM26, as well as ID11 and ID02, permitted an understanding of the very early stages of shish-kebab formation [1-4]. Our findings point to the existence, prior to nucleation, of flow-induced precursors (FIPs) consisting of non-crystalline nano bundles of stretched molecules. The key discovery is that these FIPs can be formed at temperatures higher than the material’s melting point and represent the ‘memory’ that the material has of its thermo-mechanical history. In situ observation of FIPs in melts of mixtures of high density polyethylene (HDPE), with different molecular weights, at 142°C, highlighted their fibrillar morphology and their dynamics as a function of the size. Large FIPs can crystallise (become nuclei) and grow into shish-kebabs whereas small FIPs dissolve in the melt. The presence of a critical size for nucleation is in agreement with the classical theory of nucleation. However, the same theory does not consider the formation of non-crystalline (and long lasting) structures prior to nucleation. Our experiments are, therefore, a bridge between the classical theory and new views on (flow induced) nucleation of macromolecules.

|

|

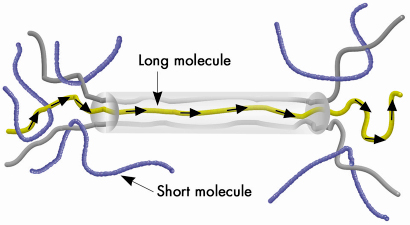

Fig. 28: Hypothetical structure of a flow-induced precursors (FIP). This is a bundle made of the longest molecules of the melt that are stretched with the application of flow. |

The dissolution of small FIPs, for which the development stops in the very early stages, occurs on the same timescale as the diffusion (reptation) of the longest molecules of the melt. This suggests that dissolution of these small FIPs is strongly correlated with the reptation of the longest molecules along the precursor backbone (Figure 28), i.e. the early FIPs are rich with the longest chains.

To summarise, in crystallisation of entangled macromolecules like polymers, morphology and structure depend on the whole thermo-mechanical history [3,4]. The memory of gradients of flow applied even at high temperatures is stored into FIPs [2]. In the very early stages of crystallisation, FIPs can direct the process towards the formation of highly anisotropic crystals with shish-kebab type morphology. The clarification of the basic mechanisms for structure formation during processing of macromolecules helps the exploitation of the properties of existing materials and could lead, eventually, to the benefit of materials with properties tailored to the application.

Authors

L. Balzano (a), G.W.M. Peters (a), S. Rastogi (b), G. Portale (c), L. Fernandez-Ballester (c) and W. Bras (c).

(a) Eindhoven University of Technology (The Netherlands)

(b) Loughborough University (UK)

(c) BM26, ESRF

References

[1] L. Balzano, N. Kukalyekar, S. Rastogi, G.W.M. Peters, J.C. Chadwick, Physical Review Letters 100, 048302 (2008).

[2] L. Balzano, Flow induced crystallization of polyolefins. PhD thesis, Eindhoven University of Technology (2008).

[3] L. Balzano, S. Rastogi, G.W.M. Peters, Macromolecules 41, 399 (2008).

[4] L. Balzano, G.Portale, S. Rastogi, G.W.M. Peters, Macromolecules 41, 5350 (2008).