ID03 Description

Main characteristics

Source: 3 undulators (two U35 and one U32) giving a flux exceeding 1013 ph/s in the whole 5-24 keV energy range.

Front end: Windowless beamline with a high power front end.

Monochromator: Liquid nitrogen cooled monolithic channel-cut Si(111).

Three optical configurations giving the following figures of merit at the sample positions:

- 50 x 30 microns (HxV, fwhm) with 1013 ph/s (toroidal mirror only)

- 20 x 15 microns (HxV, fwhm) with 1013 ph/s (toroidal mirror and KB system)

- 5 x 3 microns (HxV, fwhm) with 1012 ph/s (KB system only)

Experiment: two large hutches hosting one vertical and one horizontal geometry diffractometers allow surface x-ray diffraction studies in a variety of experimental sample environment conditions.

Synopsis

Surface X-ray diffraction is a well established technique for studying surfaces and interfaces. Even if several other techniques allow a structural determination of surfaces, X-ray diffraction offers unique possibilities:

- X-rays are weakly absorbed by matter. As consequence surface X-ray diffraction is not limited to free surfaces under UHV conditions but can be applied with success to buried solid interfaces, solid/liquid interfaces and high pressure gas/solid interfaces. This is of particular importance in the case of heterogeneous catalytic reaction where the role of the catalyst can be studied under real working conditions.

- In addition to crystallographic studies, surface diffraction is also suited for dynamical studies such as epitaxial growth, ion patterning, surface kinetics and phase transitions. In particular, ion erosion with ion beams in combination with grazing-incidence small-angle scattering has been employed to study the dynamical evolution of medium range correlations during nanopatterning.

- The possibility of tuning the photon wavelength allows to carry out experiments at resonance energies of particular elements. This is important to investigate surface magnetism in order to determine the depth distribution and magnetization of the resonant atoms. Resonance can also be used to determine the involvement and role of a particular atomic species in the surface/interface structure.

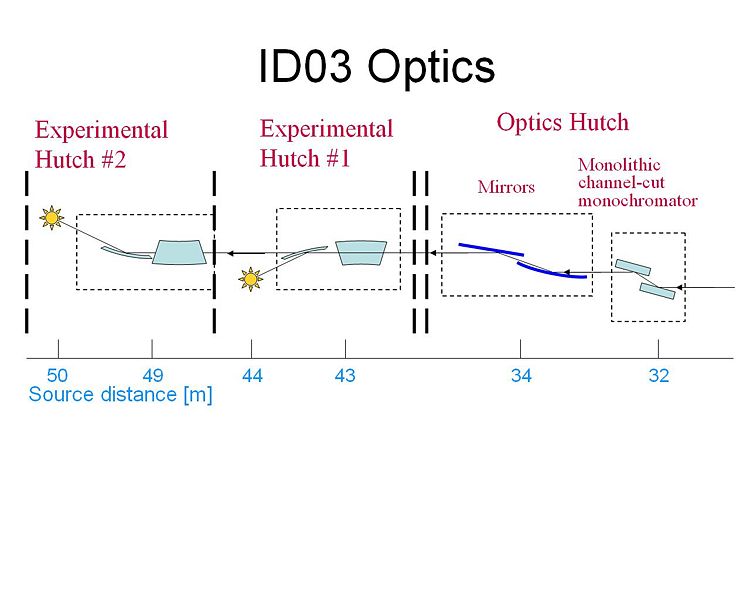

ID03 Beamline Layout along OH, EH1 and EH2

ID03 is an undulator beamline dedicated to surfaces and interfaces structural characterizations. The beamline can be used for performing static surface crystallography studies or for studying processes at surfaces in real time. The photon energy is continuously tuneable in the range 5-24 keV giving the possibility of performing measurements at resonance for a large part of the elements.

The beamline has two experimental hutches:

-

the first experimental hutch (EH1) is equipped with a z-axis vertical diffractometer, specially suited for samples with a horizontal surface geometry. Users’ chambers can be mounted on the diffractometer. The maximum load supported by the mechanics is 50 kg. The incident beam can be tilted downwards (max. angle 0.5°) by the vertical KB mirror, thus liquid surfaces are also accessible.

-

the second experimental hutch (EH2) hosts a z-axis horizontal diffractometer. The diffractometer is dedicated to Ultra-High-Vacuum studies and is coupled with a UHV chamber. The sample can be prepared in-situ and for this reason one or several K-cells or e-beam cells can be mounted on users’ demand. Ion sputtering for sample surface cleaning, and a Cylindrical Mirror Analyser (CMA) for recording Auger spectra, are available with the sample in the diffraction position. A MOKE apparatus can also be installed for in-situ magnetization measurements. The sample can be heated up to 1300 K (flash), 900 K (continuous) and cooled down to about 80 K.