One-dimensional imaging of curved surfaces using spatially resolved X-ray reflectivity

A new X-ray reflectivity method has been developed with beam sizes of a few tens of micrometres for highly curved liquid surfaces at beamline ID10, as illustrated by a graphene layer on molten copper.

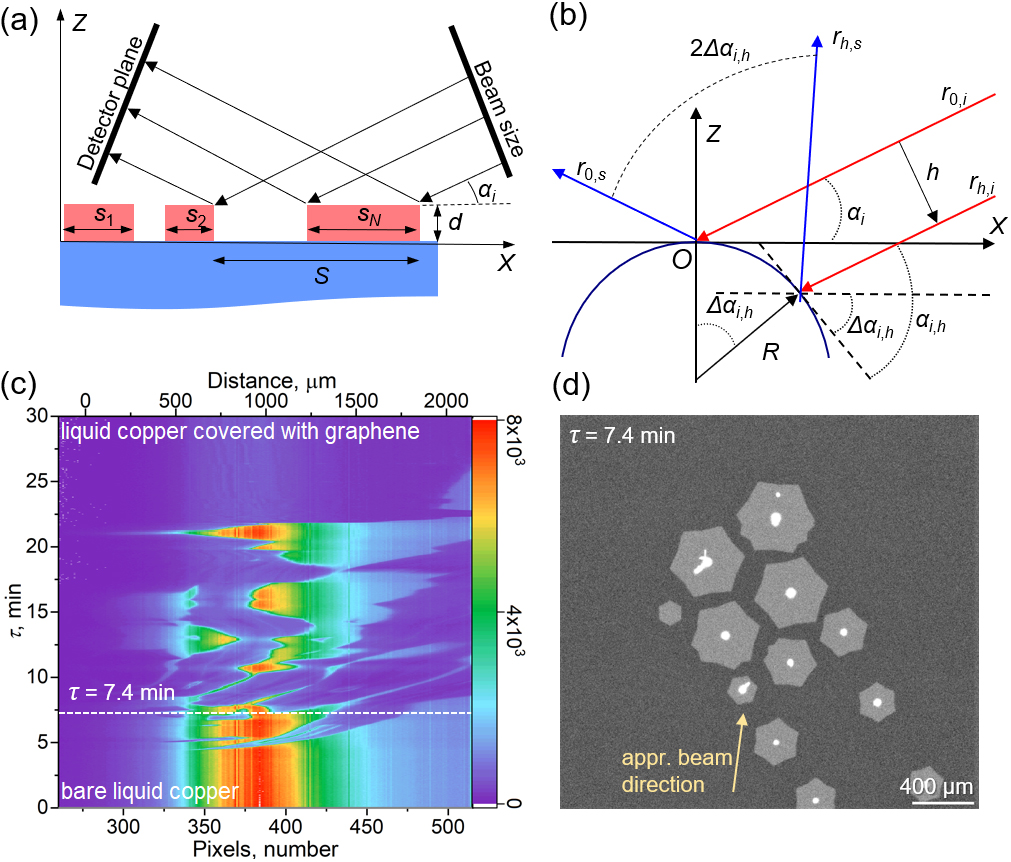

2D materials are the topic of extensive research due to their exceptional properties and potential applications in many different fields. X-ray reflectivity (XRR) is a widely used technique for studying surfaces and interfaces, including 2D materials. However, analysing partially covered (patchy) flat surfaces poses challenges for the XRR technique (Figure 1a). The application of existing techniques, such as off-specular scattering measurements and grazing-incidence small-angle X-ray scattering (GISAXS), are limited to nanoscale islands.

At ID10 a new XRR approach exploits sample curvature to visualise and analyse patches of 2D materials during their growth on curved surfaces. This methodology has been successfully applied to molten copper covered by a graphene layer grown by chemical vapor deposition (CVD). The method allows in-situ, real-time monitoring of growth kinetics, offering insights into the interfacial structure of the individual flakes at growth conditions hardly accessible by other methods.

Fig. 1: a) Example of a surface partially covered by another ultra-thin material that forms patches of thickness d and lateral sizes si smaller than the angle-dependent beam footprint S. The coverage X is ∑si /S. b) A detailed scheme where the incident beam, coming from the right side, propagates in the plane XOZ normal to the cylinder’s axis with a radius R that is perpendicular to the figure plane. h is the offset of the elementary ray rh,i from the beam centre r0,i. The angle αi is the effective grazing angle, while αi,h and Δαi,h are the actual grazing angle of rh,i and the difference of this angle from αi, respectively. c) Time-scan of the scattering signal on the detector in the vertical direction during the CVD graphene growth. The colour scale of the intensity is linear. The vertical axis represents the time after the start, and the horizontal axis is (bottom) the pixel number of the detector (along the reflected beam fan) and (top) the corresponding distance within the footprint on the sample. The regions of higher intensity correspond to the bare liquid Cu surface. The intensity is minimum when the surface is covered by graphene. d) The corresponding microscopy images for a specific moment of the growth (7.4 min after the start) are indicated with a dashed line in (c). A yellow arrow indicates the approximative direction of the incident beam.

The technique was developed for the analysis and reconstruction of XRR curves measured on surfaces with spherical or cylindrical curvature [1]. When the sample surface is curved, the reflected beam naturally spreads, leading to an image magnification on a detector (Figure 1b). The width of the spread on the detector depends on the sample curvature R, the incidence angle αi, and the sample-detector distance. This property can be harnessed for surface imaging along the X-ray beam footprint elongated in one direction due to the tiny grazing angle. In cases where the surface is partially covered with patches, the simultaneous measurement of XRR curves for both bare substrate and substrate covered with a patch are feasible. As the intensity of the reflected beam is affected by the surface electron density profile underneath it, scattering from the substrate and the covering patches can be distinguished. Compared to previous work, this study demonstrates real-time monitoring of CVD graphene growth using XRR, allowing for the characterisation of graphene crystal size, inter-flake distances, and kinetics (Figure 1c-d). Furthermore, the technique enables the simultaneous measurement of XRR curves from both bare and graphene-covered surfaces, providing insights into the adsorption height of the isolated flakes, depending on their size.

In conclusion, in-situ spatially resolved XRR on a convex sample enables imaging and qualitative characterisation of inhomogeneously covered surfaces. The innovative technique, which offers real-time monitoring with high data-acquisition rates and millisecond temporal resolution, has been validated using the growth of graphene flakes on liquid copper. The method has a wide range of research applications, including the investigation of growth and self-assembly processes in soft matter systems, the deposition of thin films or 2D materials, etc., on liquids and solid substrates, and the provision of insightful information regarding various physical and chemical parameters as a function of a coordinate on a surface. This advancement in X-ray scattering opens up new avenues for research at the ESRF.

Principal publication and authors

Employing Surface Curvature for Spatially Resolved X-Ray Reflectivity: Graphene Domains on Liquid Copper, V. Belova (a), M. Jankowski (a), M. Saedi (b), I.M.N. Groot (b), G. Renaud (c), O.V. Konovalov (a), Adv. Mater. Interfaces, 2300053 (2023); https://doi.org/10.1002/admi.202300053

(a) ESRF

(b) Leiden Institute of Chemistry (LIC), Leiden University, Leiden (The Netherlands)

(c) University Grenoble Alpes, CEA, IRIG-DEPHY-MEM, Grenoble (France)

Reference

[1] O.V. Konovalov et al., J. Synchrotron Radiat. 29 (2022).