- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2001

- Surfaces, Interfaces and Nano-science

- Self-organised Orientation of Microporous Channels in Silicalite-1 Films

Self-organised Orientation of Microporous Channels in Silicalite-1 Films

Microporous materials have attracted considerable attention in recent years as promising structures for a variety of applications such as supports for catalysts, separation membranes, functional optical coatings, selective chemical sensors, and templates for growing conductive materials. A variety of deposition strategies have been explored for the preparation of thin microporous films on different substrates including direct crystal growth in zeolite precursor mixtures, chemical modification of the substrates, and seeding with colloidal crystals prior to further hydrothermal treatment [1,2]. The functional properties of the films could be improved substantially by designing the orientation of the zeolite micro-channels, however, the corresponding processes of self-organised nucleation and crystallisation are not yet well understood.

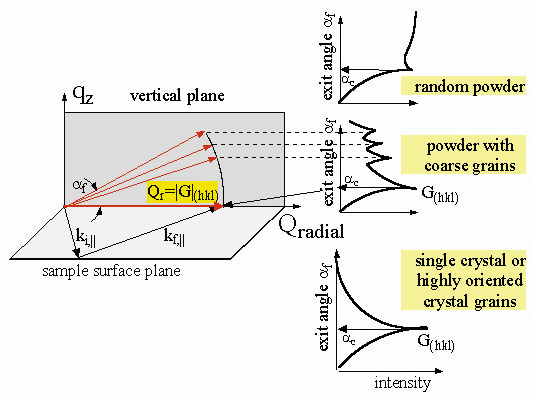

In this work, thin silicalite-1 films, grown from colloidal solution on pre-deposited seeded layers, have been investigated by grazing-incidence diffraction (GID) mainly at ID10B. This method yields 3D structural information on size and orientation of the silicalite-1 crystallites forming the film. Exploiting refraction effects at angles close to the critical angle for total external reflection, c, the structural parameters are obtained as a function of depth, thus shedding light on the nucleation process during deposition and film growth. In GID only Bragg reflections with the lattice vector G(hkl) parallel to the sample's surface can be accessed, except for those in the receptive range of the position-sensitive detector (PSD) which is placed perpendicular to the surface (see Figure 70b). The intensity distribution along the exit angle (

f) gives direct information on the orientation of those crystallites, which contribute to the Bragg reflection under investigation. The so-called "

f-spectra" expected for different grain orientation are depicted schematically in Figure 72. In all cases the intensity maximum at ac is a direct measure of the density of the film.

|

Fig. 72: The GID scattering geometry and three examples for the intensity distribution along |

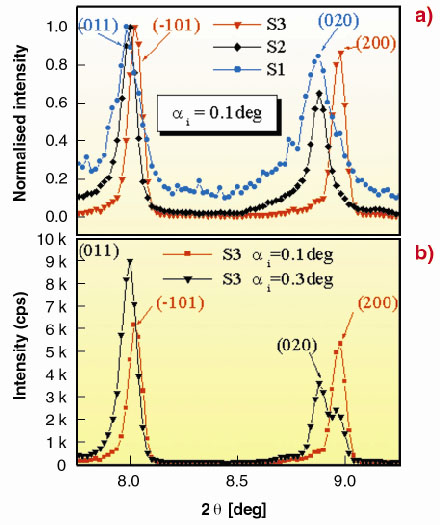

Most important for the orientation properties of the silicalite-1 crystallites is the intensity ratio of the (-101) and (011), (200) and (020) reflections, as shown in Figure 73a. The measurements are performed at I = 0.1°, which is smaller than the critical angle of 0.21° of the bulk material. The adsorbed seeded layer (S1) shows only the (011) and (020) Bragg reflections, which reveals that the crystals are oriented with the a-axes perpendicular to the substrate surface. In contrast, the grown films (S2, S3) contain only reflections with k = 0 i.e. (-101) and (200). These results clearly demonstrate the change in the crystal orientation with the a-axes from being perpendicular to parallel to the substrate surface as a function of film thickness. The zeolite orientation within the film was investigated by depth sensitive "

f-spectra" measurements at different angles of incidence (

i) for the grown film (S3). In Figure 73b the radial scans of the Bragg peaks are shown as a function of

i). In the near-surface region at about 8 nm (

i) = 0.1), the crystals are oriented with the a-axes parallel to the surface, while at a scattering depth of about 277 nm (

i) = 0.3°) most of the crystallites are oriented with the a-axes perpendicular to the surface. Two "

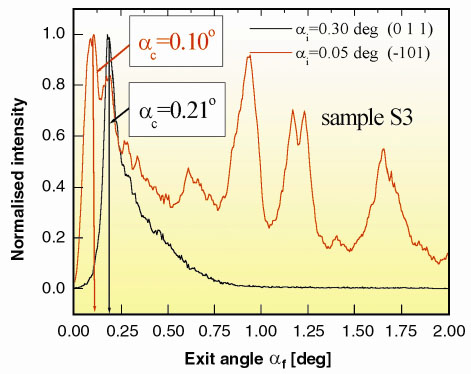

f)-spectra" of the corresponding (011) and (-101) reflections are shown in Figure 74. For a highly-grazing angle of incidence

i) = 0.05°, the intensity distribution along

f) indicates that a thin film with a low density (note that

c) = 0.1°) covers the sample which has the typical "coarse grain structure". In the case of a large penetration depth (

i) = 0.3°), the main Bragg intensity stems from a well-oriented film showing a single crystal-like feature of the "

f)-spectrum" (compare both cases with Figure 72).

|

Fig. 73: Radial 2 |

In conclusion, the change in the orientation of microporous silicalite-1 crystallites grown on silicon substrates is followed by depth-selective GID measurements. The straight channels change their orientation as a function of film thickness from being parallel to perpendicular to the surface. Laterally, the films remain in an untextured powder-like state. The underlying self-organised growth process will be studied by in situ GID measurements in the near future.

|

Fig. 74: The " |

References

[1] S. Mintova, S. Mo and T. Bein, Chem. Mater., 10, 4030-4036 (1998).

[2] S. Mintova, V. Valtchev, V. Engsrom, B.J. Schoeman and J. Sterte, J. Microporous Mater., 11, 149-160 (1997).

Principal Publications and Authors

[1] S. Mintova (a), T.H. Metzger (b) and T. Bein (a), Stud. Surf. Sci. Catal., Zeolites and Mesoporous Materials at the Dawn of the 21st Century, (Eds. A. Galarneau, F. Di. Renzo, F. Fajula, J. Verdine), Elsevier, 135, A20o04 (2001).

[2] T.H. Metzger, S. Mintova and T. Bein, Micropor. Mesopor. Mater., 43, 191-200 (2001).

(a) University of Munich (Germany)

(b) ESRF (France)